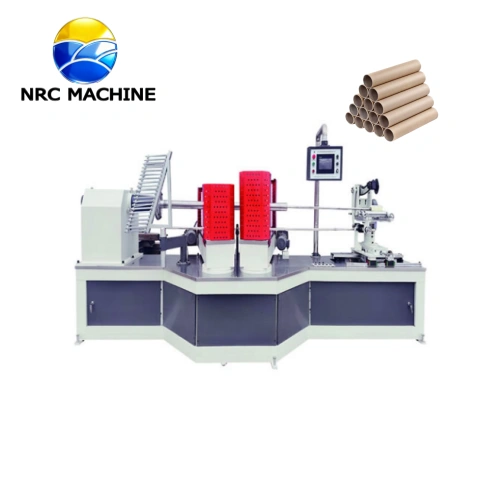

NRC200 Model Automatic Spiral Paper Tube Making Machine: Project Planning Proposal

-

Project Overview

The NRC200 Model Automatic Spiral Paper Tube Making Machine is a high-efficiency, fully automated solution designed for the industrial production of spiral-wound paper tubes. These tubes are widely used in packaging, textiles, construction, and logistics. This proposal outlines the implementation strategy for integrating the NRC200 machine into a modern manufacturing environment to enhance productivity and product consistency.

-

Technical Specifications & Features

The NRC200 model boasts advanced automation with a PLC control system and touch-screen interface, ensuring precise operation and easy parameter adjustment. It supports raw materials such as kraft paper, cardboard, and adhesive tapes, producing tubes with diameters ranging from 20mm to 200mm. The machine achieves a production speed of up to 30 meters per minute, significantly increasing output. Key features include automatic paper feeding, adhesive application, spiral winding, and continuous cutting, all integrated into a compact and energy-efficient design.

-

Operational Benefits

By deploying the NRC200, manufacturers can reduce labor costs and minimize material waste. The consistent tube quality enhances brand reliability for end customers. Its modular structure allows for quick maintenance and minimal downtime. Additionally, the machine supports customization for length, thickness, and strength, meeting diverse client specifications.

-

Implementation Plan

Phase 1 involves site assessment and infrastructure preparation, including power supply and workspace layout. Phase 2 includes machine installation, staff training, and trial production. Phase 3 focuses on performance optimization and quality assurance. A timeline of 6 weeks is estimated for full operational readiness.

-

Conclusion

The NRC200 Automatic Spiral Paper Tube Making Machine offers a scalable, cost-effective solution for modern manufacturing needs. Its integration will strengthen production capacity, improve product standards, and support business growth in competitive markets.

6.Technical Parameter

| Technical Parameters | Control System | ||

| Number of winding paper layers | 3-21 layers | PLC Controller | Delta Brand |

| Maximum coil diameter | 200mm | HMI | Color touch screen |

| Minimum coil diameter | 30mm | Program Version | HT/4.0 |

| Maximum coil thickness | 12 mm | Frequency Converter | Shenzhen EasyDrive |

| Minimum coil thickness | 1mm | Actuators (contactors, etc.) | China Chint Products |

| Core mold fixing method | Flange tightening | Signal components (photoelectric switches, etc.) | Omron Products |

| Winding head | Two head single belt | Pneumatic Components | Hengyi Products |

| Cutting method | Single blade cutting | Angle adjustment motor | Cazenove |

| Gluing method | Single/double-sided gluing | Synchronous control | X-axis servo screw |

| Fixed length method | Encoder pulse fixed length | Synchronous tracking pipe cutting system | Servo synchronous tracking multi-knife cutting |

| Number of operators | 1-2 people | ||

| Hose reel speed | 3-30 m/min | Equipped with equipment | |

| Input Power | 380V three-phase four-wire customization | Automatic pipe rack | have |

| Standard sizes | Belt diagonal | electric | |

| Host size: length × width × height | 4500mm × 1800mm × 1750mm | Belt tension adjustment | Automatic adjustment |

| Floor space: length × width | 18m × 8m | Mainframe swing angle | automatic |

| Hub height | 400mm | Automatic glue supply | Air-operated diaphragm pumps |

| Minimum wheelbase | 750mm | Automatic lubrication of paper tape | automatic |

| Maximum wheelbase | 950mm | Tension adjustment | Mechanical adjustment |

| Total mass | 3200kg | Paper holder type | Overall paper holder |

| monitor rate | 15 KW | Included accessories | |