✨Revolutionizing Industry: The Power of the * Spiral Paper Core Machine ✨

Hey everyone! 👋 Today, I’m super excited to dive into a game-changer in the manufacturing world—the * Spiral paper core machine *. If you’ve ever wondered how those sturdy tubes used in textiles, printing, or packaging are made, this machine is the hero behind the scenes! 🚀 Let’s break it down in a clear, easy-to-follow format. 📋

🌟 *What Is a * Spiral Paper Core Machine ?

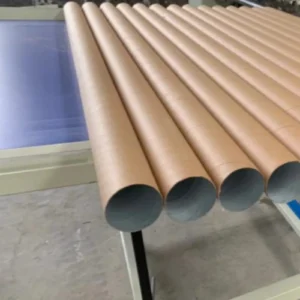

Paper core machine manufactures paper cores used in various industries. It efficiently produces high-quality cores with precision. This machine ensures consistent core dimensions, strength, and durability, meeting diverse industrial requirements effectively.The * paper core machine * is a specialized piece of equipment designed to manufacture paper cores—those cylindrical tubes you see wrapped with film, paper, or fabric. Made from layers of high-quality paper and strong adhesives, these cores are essential in industries like printing, textiles, plastics, and packaging. The * paper core machine * automates the entire process, from paper unwinding to core forming, cutting, and drying.

⚙️ How Does This Spiral Paper Core Machine Work?

Let’s peek into the process:

- Unwinding & Gluing: Multiple paper reels are unwound and coated with eco-friendly adhesive.

- Forming: The glued paper layers are wound around a mandrel to form a continuous core.

- Cutting: The long core is cut into precise lengths based on customer needs.

- Drying & Curing: Cores go through a drying system to ensure strength and stability.

- Finishing: Final inspection, labeling, and packaging for shipment.

All of this happens with incredible speed and accuracy—thanks to advanced automation and control systems.

🎯 **Key Benefits of the * Paper Core Machine ***

✅ Precision & Consistency

The * paper core machine * ensures every core has uniform diameter, length, and wall thickness—critical for high-speed industrial applications.

✅ High Efficiency

Produce hundreds of cores per hour with minimal manual intervention. Time-saving? Absolutely! ⏱️

✅ Customization

Need different sizes or strengths? No problem! These machines can be adjusted for various specifications—diameter from 1” to 10”, and lengths up to 60”.

✅ Durability & Strength

Engineered for heavy-duty use, the cores support heavy rolls without deforming—perfect for industrial environments.

✅ Eco-Friendly

Made from recyclable paper and non-toxic glue, the * paper core machine * supports sustainable manufacturing.

🏭 Industries That Rely on * Spiral Paper Core Machine * Output

- Printing & Publishing: For rolling newspapers, magazines, and labels.

- Textiles: Used in fabric and yarn winding.

- Plastics & Films: Essential for packaging films, laminates, and foils.

- Adhesives & Tapes: Core for toilet paper, tapes, and sticky rolls.

- Construction: Used in carpet and insulation material rolls.

🔮 The Future of Core Manufacturing

With rising demand for sustainable packaging and automation, the * paper core machine * is evolving fast. Smart sensors, IoT integration, and energy-efficient designs are the next big things. Manufacturers are also focusing on zero-waste production and faster changeover times.

💡 Final Thoughts

Whether you’re in manufacturing or just curious about how everyday industrial products are made, the * paper core machine * is a true innovation. It combines precision, efficiency, and sustainability—all in one powerful system. 🌍💪

If you found this insightful, drop a ❤️ and save for later! Let me know in the comments if you’d like a behind-the-scenes video of a * paper core machine * in action! 🎥👇

#ManufacturingTech #PaperCoreMachine #IndustrialInnovation #SustainablePackaging #EngineeringWonders