NRC200 Spiral Paper Tube Making Machine – Technical Specifications & Product Overview

-

Introduction

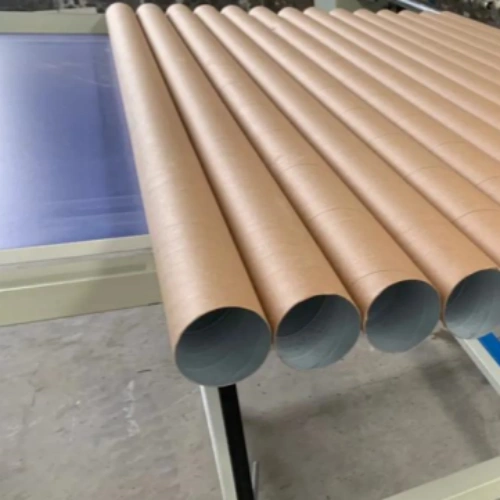

The NRC200 Spiral Paper Tube Making Machine is a high-efficiency, precision-engineered solution designed for the automated production of spiral-wound paper tubes.This machine produces spiral-wound paper tubes from paper reels. It features automatic paper feeding, adhesive application, spiral winding, and cutting. Ideal for manufacturing tubes for textiles, packaging, and construction, it ensures high precision, efficiency, and consistent tube quality. Engineered for versatility and reliability, this machine meets the demanding requirements of modern packaging, textile, paper processing, and industrial manufacturing sectors. With a wide range of adjustable parameters, it enables the production of durable, high-strength paper tubes suitable for diverse applications.

-

Key Features

- Wide Dimensional Flexibility: Capable of producing paper tubes with an inner diameter ranging from 30 mm to 200 mm.

- Adjustable Wall Thickness: Supports tube thickness from 1 mm to 15 mm, allowing customization based on strength and usage requirements.

- Spiral Winding Technology: Ensures uniform winding tension and enhanced structural integrity of the final tube.

- User-Friendly Control System: Equipped with an intuitive interface for easy parameter adjustment and process monitoring.

- High Production Efficiency: Designed for continuous, high-speed operation with minimal downtime.

- Durable Construction: Built with high-quality materials to ensure long service life and stable performance.

- Eco-Friendly Operation: Promotes sustainable packaging by using recyclable paper materials.

-

Technical Specifications

| Parameter | Specification Range |

| Model | NRC200 |

| Machine Type | Spiral Paper Tube Maker |

| Inner Diameter (ID) | 30 – 200 mm |

| Wall Thickness | 1 – 15 mm |

| Tube Length | Adjustable (model-dependent) |

| Winding Speed | High-speed, continuous mode |

| Control System | PLC + Touchscreen Interface |

| Power Supply | Standard industrial voltage |

| Raw Material | Kraft paper, linerboard, etc. |

| Glue System | Precision adhesive application |

Note: Exact tube length and speed may vary based on configuration and material used.

-

Applications

The NRC200 is ideal for manufacturing paper tubes used in:

- Textile Industry: For yarn, thread, and fabric rolls.

- Paper & Printing: Core materials for jumbo rolls, printing substrates, and adhesive tapes.

- Packaging Sector: Protective cores for steel, plastic, or film rolls.

- Construction & Industrial: Carrier tubes for technical fabrics or insulation materials.

- General Manufacturing: Custom cores for specialty applications.

-

Advantages of the NRC200

- Customization: Wide range of diameter and thickness settings enables production tailored to specific needs.

- Consistent Quality: Precision engineering ensures uniform tube dimensions and strength.

- Low Maintenance: Robust design with accessible components for easy servicing.

- Energy Efficient: Optimized power consumption without compromising output.

- Scalable Production: Suitable for both small-scale operations and large industrial lines.

-

Why Choose the NRC200?

The NRC200 stands out in the market due to its balance of flexibility, durability, and automation. Whether you’re producing lightweight cores for packaging or heavy-duty tubes for industrial use, the NRC200 delivers consistent performance. Its ability to handle a broad spectrum of specifications makes it a cost-effective investment for businesses aiming to diversify their product offerings or increase production capacity.

-

Conclusion

The NRC200 Spiral Paper Tube Making Machine is a state-of-the-art solution for modern manufacturing environments. With its 30–200 mm inner diameter range and 1–15 mm thickness capability, it offers unmatched versatility and precision. By integrating advanced technology with user-centric design, the NRC200 empowers businesses to produce high-quality, eco-friendly paper tubes efficiently and reliably.

Upgrade your production line today with the NRC200 – where innovation meets performance.

*For inquiries, technical support, or custom configurations, please contact our sales team.