From Jumbo Rolls to A4 Paper Reams: The Magic Behind A4 Paper Making Machines ✨📄

Hey everyone! 👋 Today, I’m diving into the fascinating world of paper production — specifically, how an A4 paper making machine transforms massive jumbo rolls into the neatly packed A4 paper reams we use every day. 🏭🖨️ Whether you’re in office supplies, printing, or just curious about manufacturing magic, this is a must-know process!

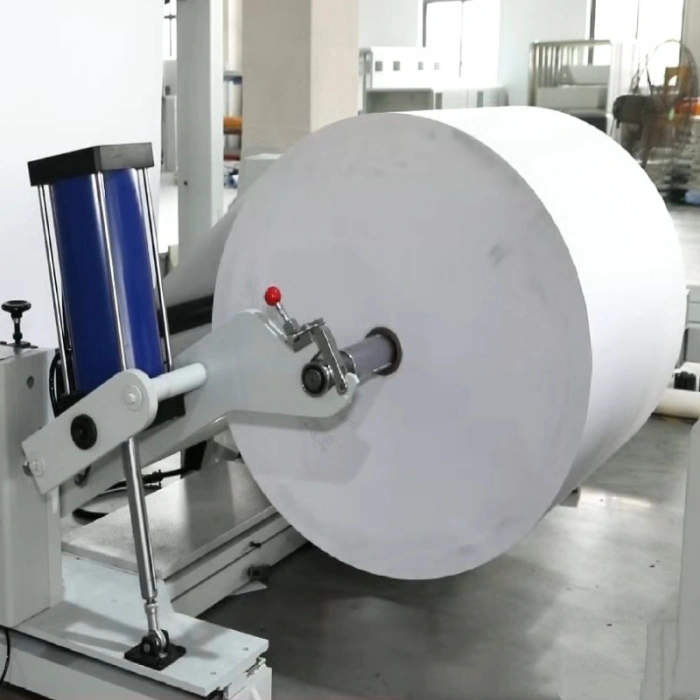

Step 1: Starting with the Giant – Jumbo Rolls 🌀

It all begins with huge, industrial-sized jumbo rolls — think of them as paper monsters, weighing hundreds of kilograms! These rolls are made from processed wood pulp and come straight from paper mills. They’re the raw material for everything that follows.

Step 2: Unwinding & Feeding into the A4 Machine 🔄

The jumbo roll is mounted onto the A4 paper making machine. It slowly unwinds, feeding the continuous paper web into the system. Precision tension control ensures the paper doesn’t tear or wrinkle. 🧩

Step 3: Cutting to Perfection – The Guillotine Action ✂️

Here’s where the real transformation happens. The machine uses ultra-sharp cutting blades to slice the wide paper roll into standard A4 size (210mm x 297mm). High-speed guillotine cutters ensure clean, accurate edges — thousands of sheets per minute! 🚀

Step 4: Counting & Stacking Like a Pro 📊

Once cut, the sheets are automatically counted (usually 500 sheets per ream) and stacked neatly. Advanced sensors detect misfeeds or double sheets, ensuring every ream is perfect. 💯

Step 5: Bundling & Packaging for Market 📦

Stacked reams are then wrapped in protective paper or plastic, labeled, and packed into cartons. Some machines even add branding or watermarks — ideal for custom office paper lines! 🏢🖨️

Machine Technical Parameter

Main technical parameters:

| Model | NRC-1100 |

| raw material maximum diameter | 1400mm |

| cutting width | 1100mm |

| cut length | 297mm |

| cutting speed | 3 reams per minute |

| Horizontal precision | ±0.2mm |

| total power | 11kw |

| machine weight | 5000kg |

| Dimensions (L×W×H) | 9200×2210×2000mm |

Why This Matters 🌍

Efficient A4 paper making machines boost productivity, reduce waste, and ensure consistent quality. They’re essential for suppliers, schools, and businesses relying on high-volume paper needs.

💡 Pro Tip: Look for machines with auto-diagnosis, low noise, and energy-saving features if you’re in the market to buy!

From giant rolls to desktop-ready reams — it’s engineering meets everyday convenience. 🙌 The next time you grab a pack of A4 paper, you’ll know the incredible journey behind it!

📌 Save this post if you love learning about manufacturing secrets!

#A4Paper #PaperMakingMachine #ManufacturingProcess #OfficeSupplies #PaperProduction #HowItWorks #FactoryTech 🏭📄✨

Stay curious, stay inspired! 💫