Product Overview

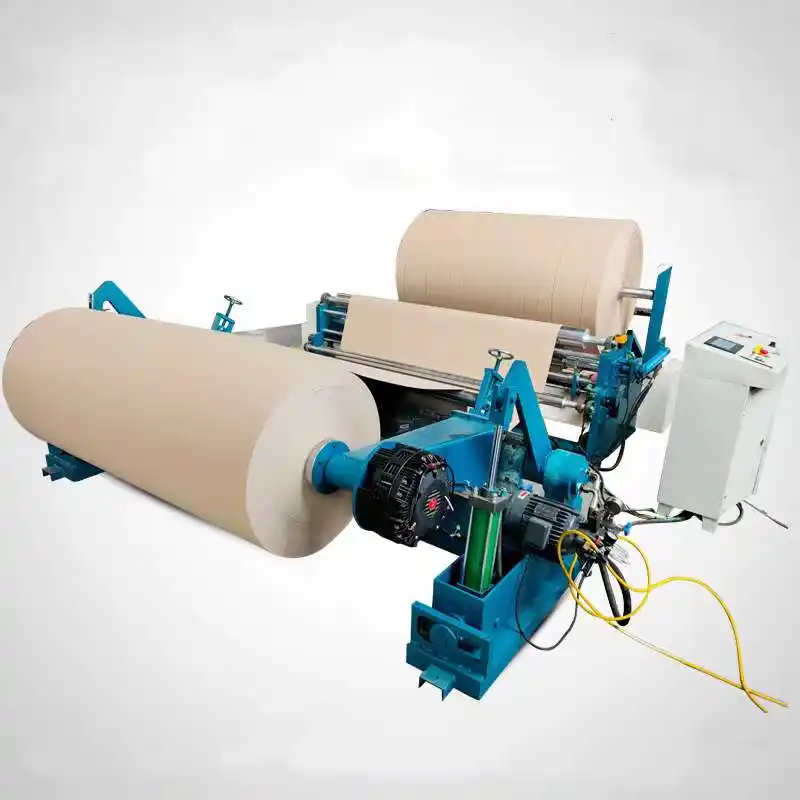

The Paper Slitting and Rewinding Machine, manufactured by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd), is a high-performance, precision-engineered solution designed for the efficient conversion of wide jumbo rolls into multiple narrow paper rolls. Combining advanced automation with robust mechanical design, this machine delivers consistent, high-quality slitting and rewinding performance for a wide range of paper products, including printing paper, packaging paper, and industrial paper rolls.

Engineered for versatility and reliability, the machine is ideal for medium to high-volume production environments in the paper processing industry. It ensures precise roll cutting, smooth operation, and minimal material waste, making it a valuable asset for enhancing production efficiency and product quality.

Key Features

- High Processing Speed: Operates at a variable speed range of 0–300 meters per minute, allowing flexible adjustment to match production demands and material characteristics.

- CNC Control System: Equipped with an advanced Computer Numerical Control (CNC) controllerfor precise operation, real-time monitoring, automatic fault diagnosis, and user-friendly interface. Enables accurate setting of slit width, tension control, and rewinding parameters.

- Hydraulic System Integration: Features a stable hydraulic systemfor automatic unwind and rewind shaft expansion/contraction, ensuring secure roll mounting and consistent tension control throughout the process.

- Precision Slitting Mechanism: Utilizes high-hardness, sharp-tipped circular rotary knives for clean, burr-free cuts. Knife positioning is adjustable to accommodate various slit widths with high accuracy.

- Fully Automated Operation: Automated loading, slitting, rewinding, and labeling processes reduce labor requirements and increase throughput.

- Tension Control System: Closed-loop tension control maintains consistent tension on both unwind and rewind stands, preventing paper stretching, tearing, or wrinkling.

- Durable Construction: Built with heavy-duty steel frame and precision components to ensure long-term stability and minimal vibration during high-speed operation.

- Safety and Compliance: Designed in accordance with international safety standards, featuring emergency stop functions, protective guards, and CE-compliant electrical systems.

Technical Specifications

| Parameter | Specification |

| Model | NRC-1600 Series (Custom Models Available) |

| Max Input Roll Width | Up to 1600 mm (customizable) |

| Max Input Roll Diameter | Up to 1300 mm |

| Min Slit Width | 10 mm (dependent on knife setup) |

| Max Output Roll Diameter | 1300 mm |

| Processing Speed | 0–300 m/min (adjustable) |

| Control System | CNC Controller with Touchscreen HMI |

| Driving System | Servo Motor + Inverter Control |

| Tension Control | Closed-loop Magnetic Powder / AC Drive |

| Rewind Shaft Type | Hydraulic Expansion Shaft |

| Power Supply | 380V, 50Hz, 3-Phase (customizable) |

| Total Power | Approx. 15–22 kW (varies by configuration) |

| Machine Dimensions (L×W×H) | Approx. 8000 × 2500 × 1800 mm (model-dependent) |

| Weight | Approx. 6000–8000 kg |

Applications

The NRC Paper Slitting and Rewinding Machine is widely used in various industries requiring precision roll conversion, including:

- Printing Industry: For slitting large rolls of offset paper, coated paper, and art paper into sheet-fed or web-fed printing sizes.

- Packaging Industry: Conversion of kraft paper, corrugated base paper, and wrapping paper for packaging lines.

- Stationery and Office Supplies: Production of narrow rolls for labels, tapes, and consumer paper products.

- Industrial Paper Processing: Slitting of specialty papers such as carbonless paper, filter paper, and electrical insulation paper.

Advantages of NRC MACHINE

- Precision & Consistency: CNC-controlled cutting ensures uniform slit width and edge quality.

- High Efficiency: Fast setup and continuous operation minimize downtime.

- Low Maintenance: Sealed bearings, lubrication systems, and wear-resistant components extend service life.

- Customization Options: Available in various configurations to meet specific customer requirements (e.g., roll width, speed, automation level).

- After-Sales Support: NRC MACHINE provides comprehensive technical support, on-site installation guidance, operator training, and spare parts supply.