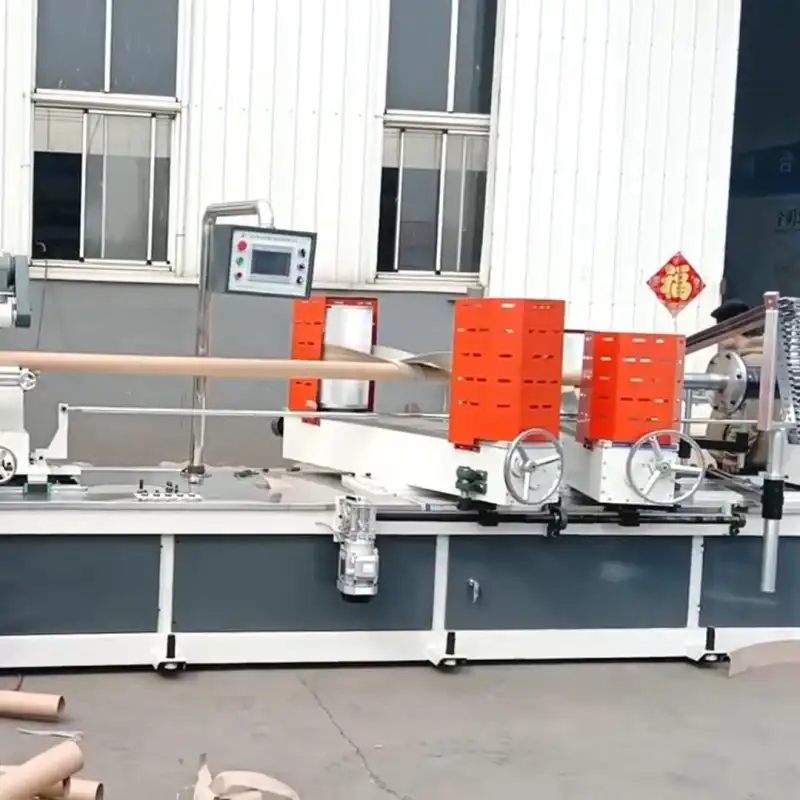

Automatic Paper Core Making Machine

by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd.)

-

Introduction

The Automatic Paper Core Making Machine, manufactured by Qingdao New Richuan Precision Machine Co., Ltd. (NRC MACHINE), represents a significant advancement in the production of high-quality paper cores for industrial applications. Designed with precision engineering and cutting-edge automation technology, this machine delivers consistent performance, high efficiency, and exceptional reliability. It is widely used in industries such as printing, packaging, paper converting, and textile winding, where uniform and durable paper cores are essential.

This comprehensive overview highlights the machine’s technical specifications, core features, operational advantages, and the technological innovations that set it apart in the global market.

-

Technical Specifications

The NRC MACHINE automatic paper core making machine is built to meet diverse production requirements with the following key technical parameters:

- Inner Diameter Range:30 mm to 200 mm

(Adjustable to accommodate various core sizes for different applications) - Wall Thickness of Paper Core:1 mm to 15 mm

(Enables customization from ultra-thin to heavy-duty cores) - Production Speed:0 to 40 meters per minute

(Variable speed control for optimal output based on material and thickness) - Drive System:High-performance servo motor driver

(Ensures precise control, smooth operation, and energy efficiency) - Control System:CNC controller (Delta brand)

(Provides intelligent operation, real-time monitoring, and easy parameter adjustment)

These specifications make the machine highly adaptable to different production needs, from small-diameter precision cores to large industrial-grade rolls.

-

Key Features and Innovations

3.1 Precision Servo Motor Drive System

Equipped with a servo motor driver, the machine achieves accurate speed and tension control throughout the winding process. This ensures uniform layering and consistent core density, minimizing defects and waste.

3.2 Advanced CNC Control (Delta Brand)

The integration of a Delta brand CNC controller allows for intuitive operation, programmable settings, and real-time diagnostics. Operators can save multiple production profiles, enabling quick changeovers between different core specifications.

3.3 Adjustable Core Dimensions

With an inner diameter range of 30–200 mm and wall thickness from 1–15 mm, the machine supports a wide variety of end-use applications. The modular design allows for fast and tool-free adjustments, reducing downtime.

3.4 High-Speed, Stable Operation

Capable of running at speeds up to 40 m/min, the machine maintains stability even at maximum throughput. Vibration damping mechanisms and balanced rolling components contribute to smooth, noise-free performance.

3.5 User-Friendly Interface

The human-machine interface (HMI) is designed for ease of use, with multilingual support, real-time status display, and fault diagnosis functions. This reduces the learning curve for operators and enhances overall productivity.

3.6 Durable Construction

Built with high-grade steel and corrosion-resistant components, the machine is designed for long-term operation in demanding industrial environments. All critical parts are sourced from trusted suppliers to ensure reliability.

-

Operational Advantages

- High Efficiency:Automated processes reduce manual labor and increase production output.

- Consistent Quality:Precision control ensures each core meets strict dimensional and structural standards.

- Low Maintenance:The robust design and high-quality components minimize breakdowns and servicing needs.

- Energy Efficient:The servo-driven system consumes less power compared to traditional motor setups.

- Flexible Production:Quick changeover between different core sizes and thicknesses supports just-in-time manufacturing.

-

Applications Across Industries

The versatility of the NRC MACHINE automatic paper core making machine makes it ideal for use in:

- Paper and Tissue Manufacturing:For winding jumbo rolls and parent rolls.

- Printing and Publishing:Producing cores for printing rolls and coated paper.

- Packaging Industry:Creating cores for adhesive tapes, labels, and flexible packaging.

- Textile Sector:Winding yarn, thread, and fabric rolls with precision.

- Industrial Converting:Used in laminating, slitting, and rewinding lines.

Its adaptability ensures seamless integration into existing production lines across multiple sectors.

-

Why Choose NRC MACHINE?

Qingdao New Richuan Precision Machine Co., Ltd. is committed to innovation, quality, and customer satisfaction. With years of experience in designing and manufacturing precision winding equipment, NRC MACHINE offers:

- Technical Expertise:Engineered by a team of skilled professionals using the latest CAD and simulation tools.

- Global Compliance:Machines meet international safety and performance standards.

- After-Sales Support:Comprehensive service, training, and spare parts availability.

- Customization Options:Available upon request to meet specific client requirements.

Choosing NRC MACHINE means investing in a reliable, future-ready solution for paper core production.

For inquiries or custom solutions, please contact:

Qingdao New Richuan Precision Machine Co., Ltd. (NRC MACHINE)

Email: james@nrcmachine.com

Phone: +86 15254213289

Website: https://nrcmachine.com