Corner Protector Machine: The Ultimate Solution for Edge Protection by NRC MACHINE

Introduction to the Corner Protector Machine

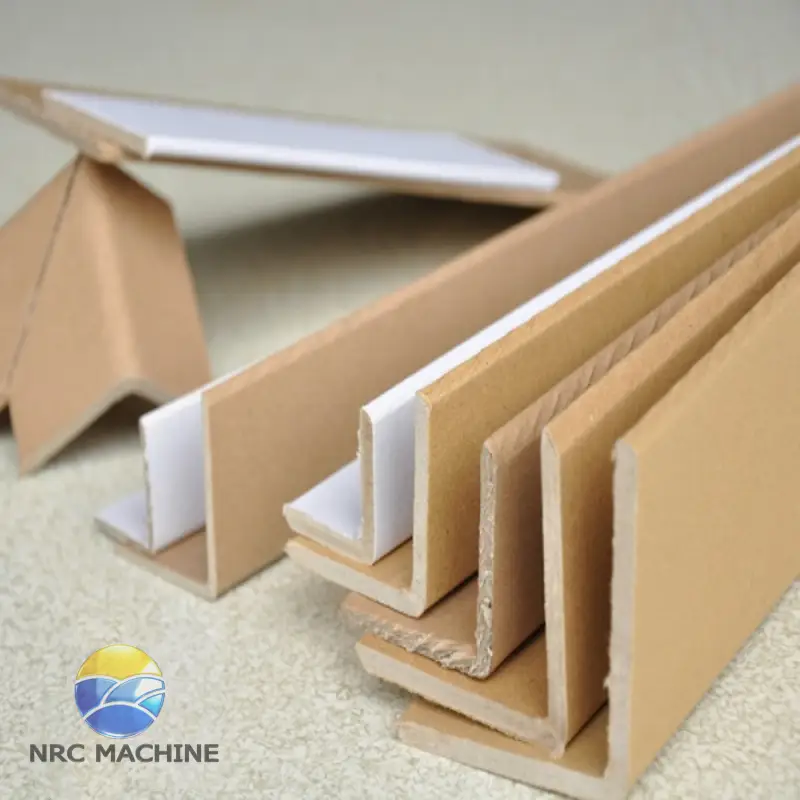

Corner Protector Machine, is engineered to convert waste paper or kraft paper into high-strength, eco-friendly paper corner protectors.In the world of packaging and material handling, protecting the edges of cardboard boxes, pallets, and fragile goods is crucial to ensuring product integrity during transit and storage. This is where the corner protector machine comes into play. Engineered for precision, efficiency, and durability, the corner protector machine manufactured by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd) stands out as a leading solution in the global market.

Designed to produce high-quality corner protectors from kraft paper, cardboard, or composite materials, this machine delivers consistent performance for industries ranging from logistics and warehousing to furniture and electronics manufacturing.

Why Choose NRC MACHINE’s Corner Protector Machine?

NRC MACHINE has built a strong reputation for innovation and reliability in packaging machinery. Their corner protector machine is no exception. Here’s what sets it apart:

- High-Speed Production: Capable of producing up to 60meters per minute, this machine maximizes output without compromising on quality.

- Precision Engineering: Equipped with advanced PLC control systems and servo-driven mechanisms, the machine ensures accurate cutting, folding, and gluing.

- Flexible Material Compatibility: Works seamlessly with various materials, including single/double wall corrugated paper, kraft paper, and laminated boards.

- User-Friendly Interface: The touch-screen control panel allows operators to adjust settings easily, reducing downtime and training time.

- Low Maintenance & Energy Efficiency: Built with robust components and optimized power consumption, the machine reduces long-term operational costs.

Whether you’re protecting delicate corners of wooden crates or reinforcing cardboard boxes for export, the corner protector machine from NRC MACHINE provides a cost-effective and sustainable edge protection solution.

How the Corner Protector Machine Works

The working process of the corner protector machine is both efficient and intelligent:

- Unwinding: Raw material (paper roll) is loaded and unwound automatically.

- Gluing & Shaping: The paper passes through precision rollers and is coated with eco-friendly adhesive, then shaped into a 90-degree angle.

- Cutting: The continuous strip is cut to desired lengths using a high-speed rotary cutter.

- Stacking: Finished corner protectors are collected in an organized stack, ready for packaging.

This fully automated process minimizes human intervention and ensures uniform product quality—critical for meeting industrial standards.

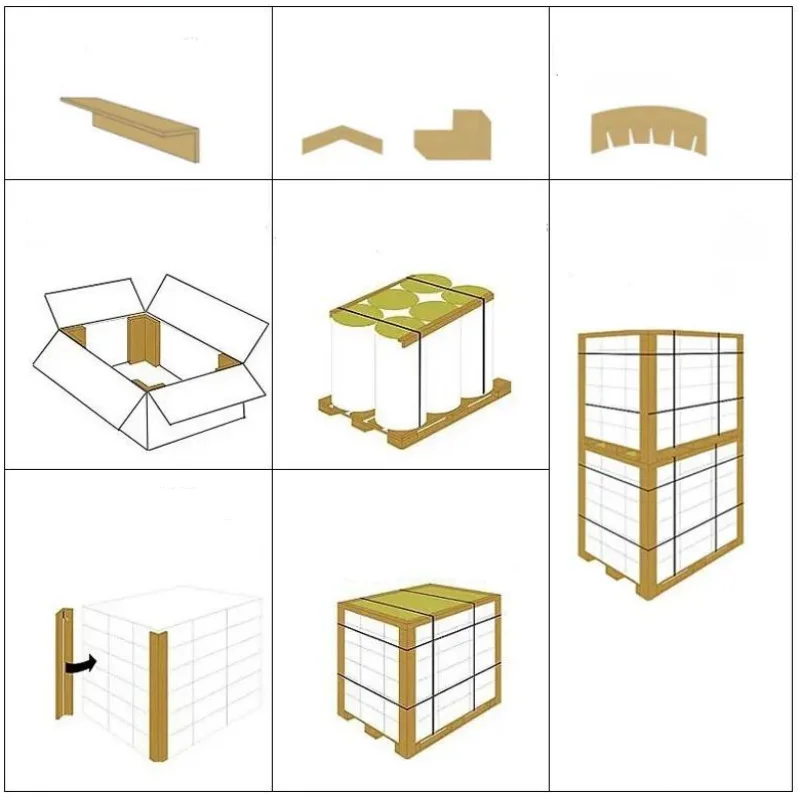

Applications of Corner Protectors Produced by the Machine

The corner protectors made by NRC’s corner protector machine are widely used across multiple industries:

- Furniture & Wood Products: Prevent chipping and damage during shipping.

- Electronics & Appliances: Reinforce box corners to protect sensitive internals.

- Ceramics & Glassware: Add structural support to fragile packaging.

- Logistics & Export: Enhance stacking strength and reduce transit damage.

With customizable sizes, thicknesses, and strength levels, the corner protector machine enables businesses to tailor solutions to their specific needs.

Sustainability and Environmental Benefits

In today’s eco-conscious market, sustainability matters. The corner protector machine supports green initiatives by:

- Using recyclable paper-based materials.

- Minimizing waste through precise cutting and alignment.

- Eliminating the need for plastic corner guards.

By switching to paper corner protectors produced by NRC’s machine, companies can reduce their carbon footprint and meet international environmental standards—such as those in the EU and North America—more effectively.

Technical Parameter

| Paper Angle Protection Specification | width:25-100mm |

| Length 50-9000mm | |

| thickness:2-8mm | |

| Production speed | 0-60m/min |

| Host power | 11kw+4.3kw |

| Control mode | numerical control |

| Raw material | surface paper 150g-220g |

| Core paper 300g-700g | |

| Cutting mode | Servo tracking cutting |

Global Reach and After-Sales Support

As a trusted manufacturer, NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd) exports its corner protector machine to over 50 countries, including the USA, Germany, Australia, and Southeast Asian nations. The company offers:

- Factory installation and training

- Remote troubleshooting via IoT monitoring

- Spare parts supply and technical support

Their commitment to customer satisfaction ensures that every corner protector machine operates at peak performance throughout its lifecycle.

Conclusion: Invest in the Future with NRC’s Corner Protector Machine

The corner protector machine is more than just a piece of equipment—it’s a strategic investment in product safety, operational efficiency, and environmental responsibility. With NRC MACHINE’s advanced technology, global experience, and customer-centric service, businesses can stay ahead of the competition.

Don’t let damaged goods affect your reputation. Choose the corner protector machine from NRC MACHINE and elevate your packaging standards today.

Contact NRC MACHINE now to request a demo, quote, or technical specification sheet.