The Rising Tide of the Paper Core Market: Innovation, Sustainability, and the NRC Machine Advantage

Introduction: A Core Component in Modern Industry

In the evolving landscape of industrial packaging and material handling, the paper core market has emerged as a silent yet indispensable force. From textile rolls to printing substrates, paper cores serve as foundational elements across diverse sectors. As global demand for sustainable and cost-effective packaging solutions grows, the paper core market is experiencing a renaissance—driven by technological innovation, environmental consciousness, and the rising adoption of high-efficiency production equipment.

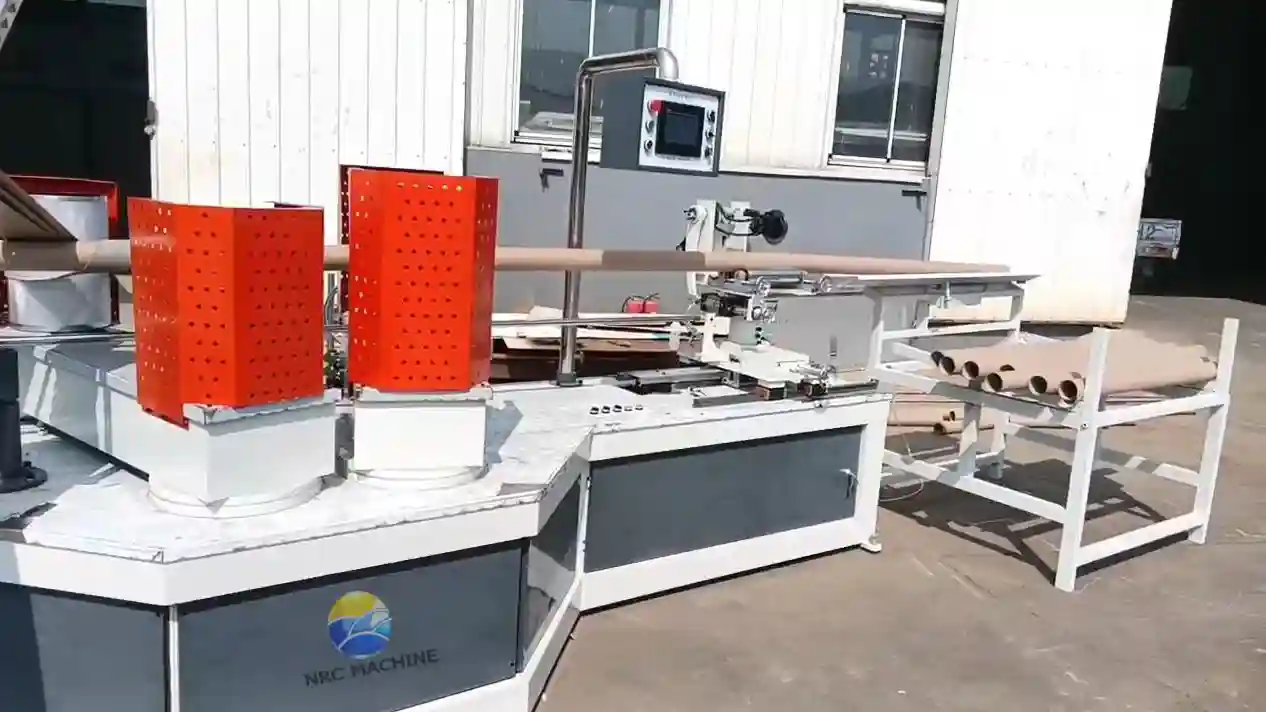

At the heart of this transformation lies a key enabler: the paper core making machine made by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd). This Chinese engineering powerhouse is redefining how paper cores are manufactured, setting new benchmarks for precision, speed, and reliability.

Chapter 1: Market Dynamics Reshaping the Paper Core Industry

The paper core market is no longer a niche segment. Valued at over USD 3 billion in 2024, it is projected to grow at a CAGR of 5.8% through 2030. This growth is fueled by several converging trends:

- Sustainability mandates: With plastic restrictions tightening worldwide, industries are shifting to paper-based alternatives. Paper cores, being fully recyclable and biodegradable, are in high demand.

- E-commerce expansion: The surge in online retail has increased the need for durable, lightweight packaging—paper cores play a critical role in roll packaging for labels, films, and protective wraps.

- Industrial automation: As manufacturing lines become faster and more precise, the demand for uniformly wound materials on high-quality paper cores has surged.

These factors are not only expanding the market size but also raising performance expectations—pushing manufacturers to adopt advanced machinery.

Chapter 2: Engineering Excellence – The NRC MACHINE Edge

At the forefront of this technological leap is the paper core making machine made by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd). Designed for scalability and precision, NRC’s machines offer:

- High-speed production: Capable of producing up to 120 cores per minute, meeting the demands of large-scale operations.

- Customizable specifications: Adjustable inner diameter, length, and wall thickness to serve diverse industry needs—from narrow labels to wide industrial films.

- Smart control systems: Integrated PLC and HMI interfaces allow real-time monitoring, reducing downtime and operator error.

- Energy-efficient design: Lower power consumption and minimal material waste align with green manufacturing goals.

What sets NRC apart is its commitment to R&D. With over 15 years of experience, the company has optimized every stage of the paper core making process—winding, gluing, cutting, and stacking—ensuring consistent quality and operational efficiency.

Chapter 3: Sustainability at the Core – A Green Future for Packaging

As environmental regulations tighten, the paper core market is becoming a poster child for circular economy principles. Unlike plastic cores, paper cores can be easily recycled or repurposed into new paper products, reducing landfill burden.

NRC MACHINE supports this sustainability drive by engineering machines that:

- Use water-based adhesives, eliminating harmful VOC emissions.

- Optimize raw material usage through precision winding algorithms.

- Enable the use of recycled paperboard without compromising core strength.

This eco-conscious approach is resonating with global clients, particularly in Europe and North America, where ESG compliance is a boardroom priority. As a result, the paper core making machine made by NRC MACHINE is not just a production tool—it’s a sustainability enabler.

Chapter 4: Global Reach and Future Outlook

NRC MACHINE has successfully exported its paper core making machines to over 30 countries, including Germany, India, Brazil, and Vietnam. Their success underscores a broader trend: the globalization of the paper core market, where quality, reliability, and innovation trump geographic origin.

Looking ahead, the integration of IoT and AI in paper core production lines—already in development at NRC’s Qingdao facility—promises even greater automation, predictive maintenance, and data-driven optimization.

With such advancements, the paper core market is poised to evolve from a commodity-driven sector to a high-tech, value-added industry. And at the center of this evolution stands NRC MACHINE, turning paper into precision, one core at a time.

Conclusion: Reinventing the Core of Industry

The paper core market is undergoing a quiet revolution—one driven by technology, sustainability, and global demand. As industries seek greener, smarter packaging solutions, the role of advanced machinery becomes paramount. The paper core making machine made by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd) exemplifies this shift, offering a blend of performance, efficiency, and environmental responsibility.

For manufacturers aiming to stay competitive, investing in innovation is no longer optional—it’s essential. And as the paper core market continues to expand, companies like NRC MACHINE are proving that even the most humble components can drive monumental change.