Revolutionizing the Paper Tube Industry: Advanced Paper Tube Manufacturing Equipment by NRC MACHINE

In the rapidly evolving packaging and material processing industry, the demand for high-quality, efficient, and precision-driven paper tube manufacturing equipment has surged. At the forefront of this innovation stands NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd), a trusted name in designing and manufacturing state-of-the-art machinery tailored for modern production needs. With a focus on automation, precision, and reliability, NRC MACHINE delivers paper tube manufacturing equipment that sets new benchmarks in performance and output quality.

Innovative Technology Behind NRC MACHINE’s Paper Tube Manufacturing Equipment

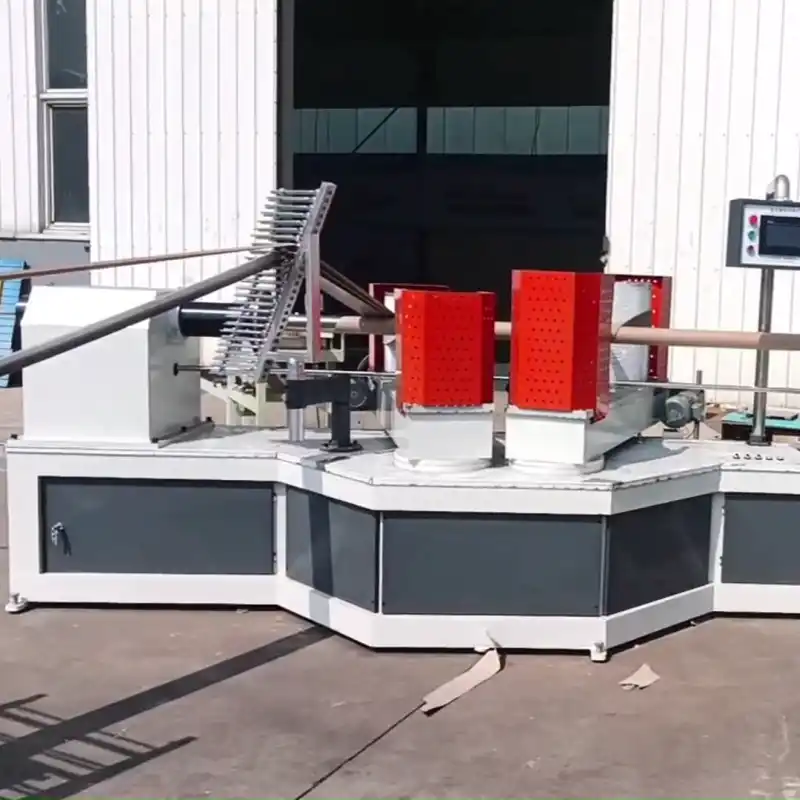

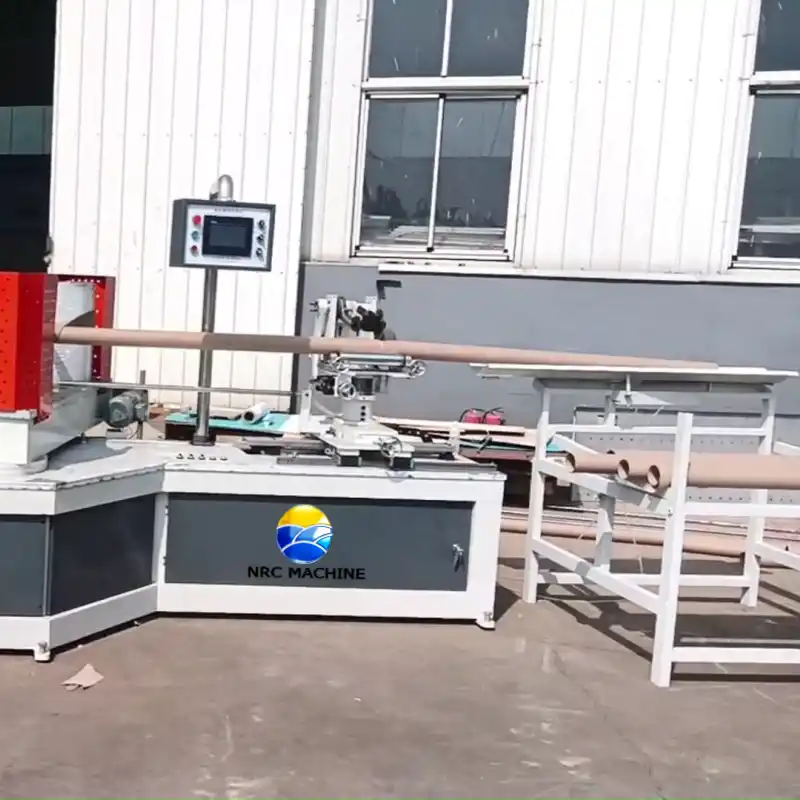

At the heart of NRC MACHINE’s success lies its integration of cutting-edge technology. Each unit of paper tube manufacturing equipment is engineered with a servo motor driver and a CNC controller, ensuring unmatched precision, speed, and repeatability. The servo motor system allows for smooth, responsive control during high-speed operations, minimizing material waste and maximizing production efficiency. Meanwhile, the CNC controller provides intuitive operation, real-time monitoring, and easy parameter adjustments, making the machine adaptable to various production requirements.

This advanced control system enables operators to store multiple production recipes, reducing setup time when switching between different paper tube specifications. Whether you’re producing cores for textiles, adhesive tapes, or industrial laminates, this level of automation ensures consistent quality across batches.

Precision Engineering: Technical Details That Set the Standard

NRC MACHINE’s paper tube manufacturing equipment is built to meet diverse industrial needs with remarkable technical capabilities. Key specifications include:

- Inner Diameter Range: 30–200 mm – suitable for a wide array of applications across industries

- Wall Thickness of Paper Tube: 1–15 mm – allowing customization from lightweight cores to heavy-duty industrial tubes

- Fully adjustable settings for length, winding tension, and glue application

- High-speed winding mechanism with automatic paper feeding and cutting

These technical details reflect the machine’s versatility and precision. The wide range of inner diameters and wall thicknesses makes it ideal for manufacturers serving multiple sectors, from packaging and printing to textile and construction materials. The equipment’s robust construction and fine-tuned mechanics ensure that every paper tube produced meets strict dimensional and strength standards.

Why Choose NRC MACHINE for Your Paper Tube Production Needs?

Investing in paper tube manufacturing equipment is a strategic decision that impacts your production efficiency, product quality, and long-term profitability. NRC MACHINE stands out for several compelling reasons:

- Reliability & Durability: Built with high-grade components and rigorous quality control, NRC machines are designed for continuous operation in demanding environments.

- User-Friendly Interface: Thanks to the CNC controller, operators can manage complex processes with minimal training, reducing downtime and human error.

- Customization & Support: NRC MACHINE offers tailored solutions based on client requirements, backed by comprehensive after-sales service, technical training, and spare parts availability.

- Global Compliance: All equipment meets international safety and environmental standards, ensuring smooth integration into global supply chains.

From startup producers to large-scale industrial plants, businesses worldwide are turning to NRC MACHINE to upgrade their production lines with intelligent, efficient, and future-ready paper tube manufacturing equipment.

The Future of Sustainable and Smart Paper Tube Manufacturing

As industries move toward eco-friendly packaging solutions, the role of advanced paper tube manufacturing equipment becomes even more critical. Paper tubes offer a renewable, recyclable alternative to plastic and metal cores, aligning with global sustainability goals. NRC MACHINE is committed to supporting this green transition by delivering energy-efficient, low-waste machinery that combines environmental responsibility with high productivity.

With ongoing R&D investments, NRC MACHINE continues to enhance its servo-driven, CNC-controlled systems, integrating IoT capabilities for remote monitoring and predictive maintenance—ushering in a new era of smart manufacturing.

Conclusion: Partner with NRC MACHINE for Next-Gen Paper Tube Solutions

In a competitive market, the right equipment can be the difference between merely surviving and thriving. Paper tube manufacturing equipment from NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd) delivers the precision, flexibility, and reliability modern manufacturers demand. Whether you’re launching a new product line or upgrading your current facility, choosing NRC MACHINE means investing in innovation, quality, and long-term success.

Discover the power of automation, precision, and sustainability—explore the full range of paper tube manufacturing equipment from NRC MACHINE today and take your production to the next level.