✨Revolutionize Your Production: Automatic Paper Tube Cutting Machine✨

🌟 Introduction: Embrace Efficiency & Precision

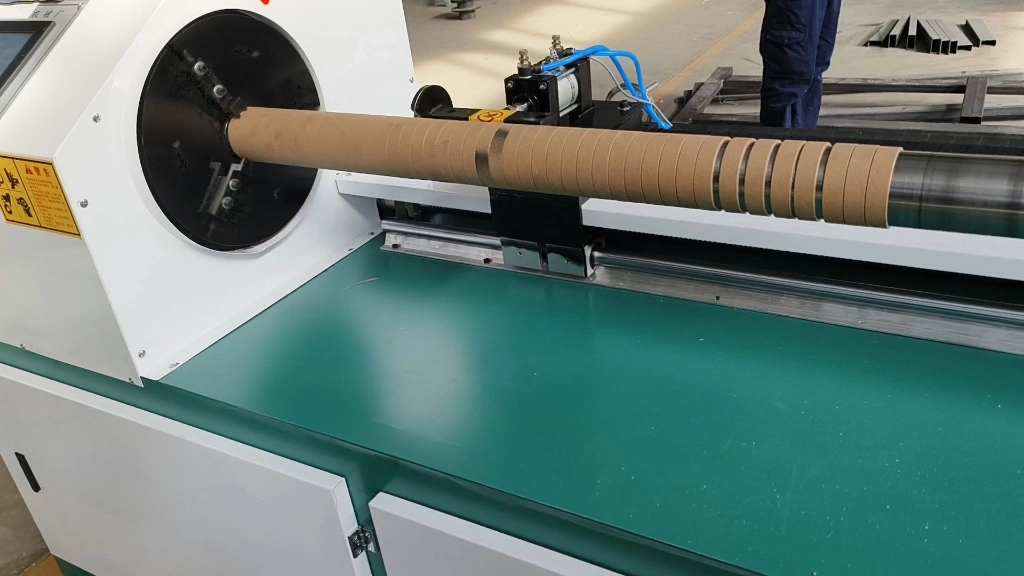

In the fast-paced packaging and printing industry, time and accuracy are everything. Meet the Automatic Paper Tube Cutting Machine—a game-changing solution designed to streamline your operations, reduce labor costs, and ensure impeccable cutting precision every time. Say goodbye to manual errors and hello to smart automation!

🔧 Key Features That Stand Out

✅ Automatic Loading & Unloading System

This machine is equipped with an intelligent auto-loading and unloading mechanism. No more manual feeding or handling—simply set it up, and let it work seamlessly. It significantly reduces labor dependency and boosts overall productivity.

✅ Advanced CNC Controller

Powered by a high-performance CNC (Computer Numerical Control) system, this machine offers precise control over cutting length, speed, and quantity. The user-friendly interface allows operators to input specifications with ease, ensuring consistent, accurate cuts down to the millimeter.

✅ High-Speed & High-Precision Cutting

Whether you’re processing paper tubes for textiles, printing, or industrial use, this machine delivers clean, burr-free cuts at high speeds. Its durable blade system and stable structure ensure long-term reliability.

✅ Smart Safety Protection

Designed with safety in mind, the machine includes emergency stop functions, protective covers, and automatic fault detection—ensuring a secure working environment.

🏭 Ideal Applications

Perfect for factories producing paper tubes for:

- Textile industry (yarn, thread)

- Printing & packaging (labels, films)

- Industrial rolls (adhesives, foils)

- Daily necessities (toilet paper, paper towels)

💡 Why Choose This Machine?

✔️ Increases production efficiency by up to 300%

✔️ Reduces material waste and labor costs

✔️ Easy to operate and maintain

✔️ Fully customizable to meet your production needs

📌 Technical Specifications & Dimensions

Technical Parameters:

| Parameter | Specification |

| Max. Cutting Diameter | Ø 30-150 mm (Customizable) |

| Thickness of paper tube wall | 1~20mm |

| Max. Cutting Length | 10-1500 mm (Customizable) |

| Cutting Speed | Up to 60 cuts/min (Depends on material and thickness) |

| Cutting Precision | ±0.1 mm |

| CNC Controller | Siemens S7-1200 PLC (User-Friendly Touchscreen Interface) |

| Blade System | High-speed steel blade with auto-lubrication system (Replaceable) |

| Power Supply | 380V/50Hz, 3-phase (or customized for local requirements) |

| Motor Power | 4.5 kW (Main Cutting Motor) + 2.2 kW (Loading/Unloading Motors) |

| Air Pressure Requirement | 0.6-0.8 MPa (for pneumatic components) |

| Machine Weight | 2500 kg |

| Ambient Temperature | 0-40°C (Operational), 20-80% RH (Non-condensing) |

| Certifications | CE, ISO 9001:2015, ROSH Compliance |

Machine Dimensions:

| Dimension | Size (L × W × H) |

| Overall | 4000 mm × 2000 mm × 2200 mm |

| Footprint | 3500 mm × 1800 mm (Approximate) |

| Loading Height | 850 mm (Adjustable ±50 mm) |

📌 Final Thoughts

Upgrading to automation isn’t just a choice—it’s a necessity for staying competitive. The Automatic Paper Tube Cutting Machine combines cutting-edge technology with robust performance, making it the ultimate investment for modern manufacturing.

📩 Interested? DM me for a demo video or quotation! Let’s take your production line to the next level together! 🚀

#PaperTubeMachine #AutomationTechnology #CNCManufacturing #SmartFactory #IndustrialInnovation #PackagingSolutions #EfficiencyUpgrade

Follow for more insights on industrial automation & smart manufacturing! 🔧📊

🧠 Why These Specs Matter:

- Versatility:The wide range of cutting diameters and lengths ensures compatibility with diverse paper tube sizes.

- Accuracy & Speed:±0.1 mm precision and high-speed cutting balance efficiency and quality.

- Customization:Adjustable loading height and customizable dimensions allow seamless integration into existing lines.

- Safety & Compliance:CE/ISO certifications ensure global regulatory adherence.

Contact Us Today! 📞

Let our experts help you optimize your production process. Request a quote or schedule a virtual tour now! 🤝

Note: Specifications may vary slightly based on customization requests. Please consult our team for detailed engineering drawings and tailored solutions