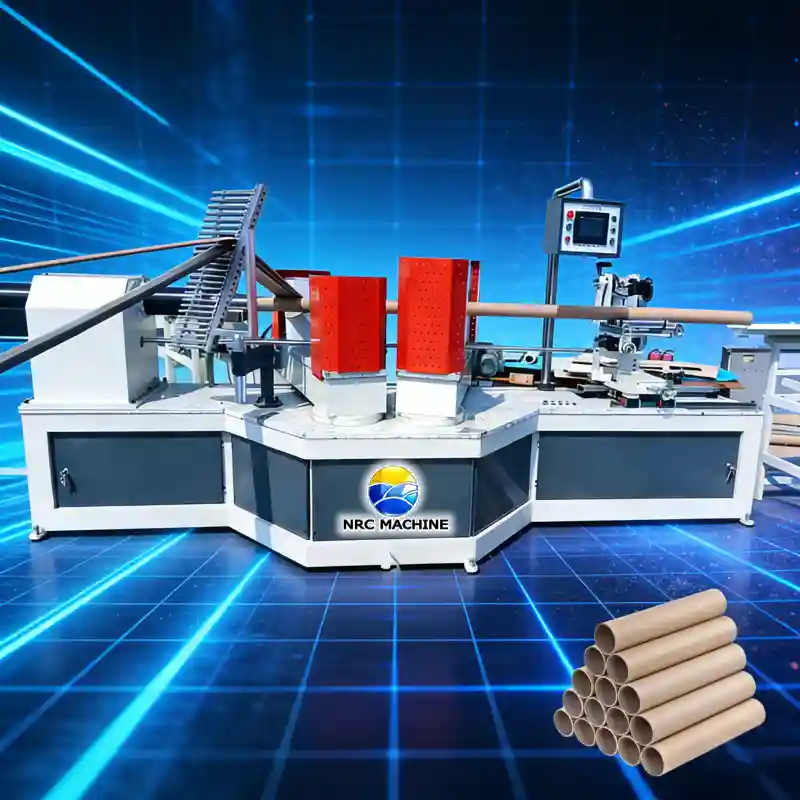

CNC Paper Tube Making Machine by NRC MACHINE

Introduction

In the ever-evolving world of packaging and industrial manufacturing, efficiency, precision, and customization are key drivers of success. One innovation that has significantly transformed the paper tube production industry is the CNC Paper Tube Making Machine. Engineered for high performance and reliability, this advanced machinery is redefining how paper tubes are manufactured across various sectors—including packaging, textiles, printing, and construction. Made by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd), a leading name in precision engineering, the CNC Paper Tube Making Machine combines cutting-edge technology with user-friendly operation to deliver consistent, high-quality output.

What Is a CNC Paper Tube Making Machine?

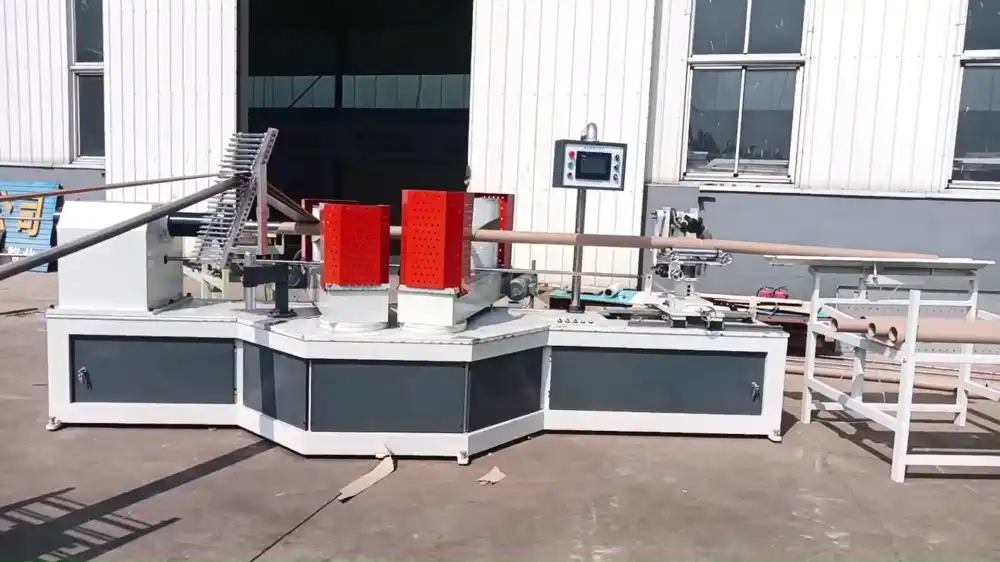

A CNC Paper Tube Making Machine is an automated system designed to produce paper tubes with exceptional accuracy and speed. Unlike traditional manual or semi-automatic machines, this machine leverages computer numerical control (CNC) technology to precisely manage every stage of the tube-forming process. From winding and gluing to cutting and finishing, the entire workflow is optimized for minimal waste and maximum productivity.

The model developed by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd) stands out due to its robust construction, intelligent control systems, and wide processing capabilities. With an inner diameter ranging from 30 to 200mm and a thickness capacity of 1 to 15mm, it can handle a diverse range of paper tube specifications, making it ideal for both small-scale operations and large industrial production lines.

Key Features of the CNC Paper Tube Making Machine by NRC MACHINE

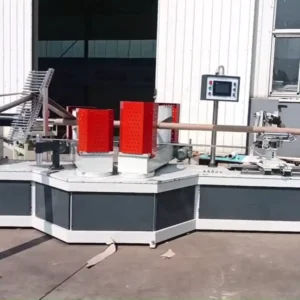

- Precision CNC Controller

At the heart of the machine lies a state-of-the-art CNC controller that ensures accurate parameter settings and real-time monitoring. This allows operators to set exact dimensions, control winding speed, and adjust pressure settings with ease. The result is uniform tube quality, batch after batch. - High-Performance Servo Motor Driver

Equipped with a servo motor driver, the machine delivers smooth, responsive, and energy-efficient operation. The servo system enables precise synchronization of all moving parts, reducing vibration and wear while enhancing overall stability and lifespan. - Wide Processing Range

The machine supports an inner diameter of 30~200mmand can produce tubes with a thickness of 1~15mm, accommodating everything from lightweight postal tubes to heavy-duty industrial cores. This flexibility makes it a versatile solution for multiple applications. - Customization Support

Understanding that different industries have unique requirements, NRC MACHINEoffers full customization options. Whether you need special feeding systems, integrated cutting units, or specific control interfaces, the CNC Paper Tube Making Machine can be tailored to meet your exact production needs. - User-Friendly Interface and Maintenance Design

The machine features an intuitive HMI (Human-Machine Interface) that simplifies operation, even for less experienced staff. Additionally, its modular design allows for quick maintenance and part replacement, minimizing downtime.

Why Choose the CNC Paper Tube Making Machine from NRC MACHINE?

Choosing the right machinery is critical to staying competitive in today’s fast-paced market. The CNC Paper Tube Making Machine made by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd) offers several compelling advantages:

- Consistent Quality: CNC-controlled processes eliminate human error, ensuring every tube meets strict dimensional and structural standards.

- Increased Productivity: Automation reduces cycle times and labor costs, enabling higher output with fewer resources.

- Energy Efficiency: The servo-driven system consumes less power compared to traditional motor setups, contributing to lower operational costs and a smaller carbon footprint.

- Global Compliance and Reliability: Built with high-grade components and adhering to international quality standards, the machine is trusted by clients worldwide.

Moreover, the fact that this CNC Paper Tube Making Machine is engineered and manufactured by a reputable company like NRC MACHINE adds an extra layer of confidence. With years of experience in precision machinery development, they ensure every unit leaving their facility meets the highest benchmarks of performance and durability.

Applications Across Industries

The versatility of the CNC Paper Tube Making Machine makes it indispensable in numerous industries:

- Packaging: For shipping tubes, gift wraps, and protective sleeves.

- Textiles: Used as warp beams and fabric cores.

- Printing and Paper: Ideal for producing cores for rolls of paper, film, or foil.

- Construction and Composites: Produces strong, durable tubes for concrete forms or structural components.

Thanks to its wide processing range and customization capabilities, the machine easily adapts to the demands of these diverse sectors.

Conclusion: The Future of Paper Tube Manufacturing Is Here

The CNC Paper Tube Making Machine represents a significant leap forward in manufacturing technology. Made by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd), it combines precision, power, and flexibility into one powerful system. With an inner diameter range of 30~200mm, thickness capability of 1~15mm, advanced servo motor driver, intelligent CNC controller, and full customization support, it is perfectly suited for modern production environments that demand both quality and adaptability.

If you’re looking to upgrade your paper tube production line, the CNC Paper Tube Making Machine is an investment that delivers long-term value, efficiency, and scalability. Contact NRC MACHINE today to learn more about how their innovative solutions can transform your operations.