Paper Core Making Machine Price – High-Performance Solution by NRC MACHINE

-

Introduction

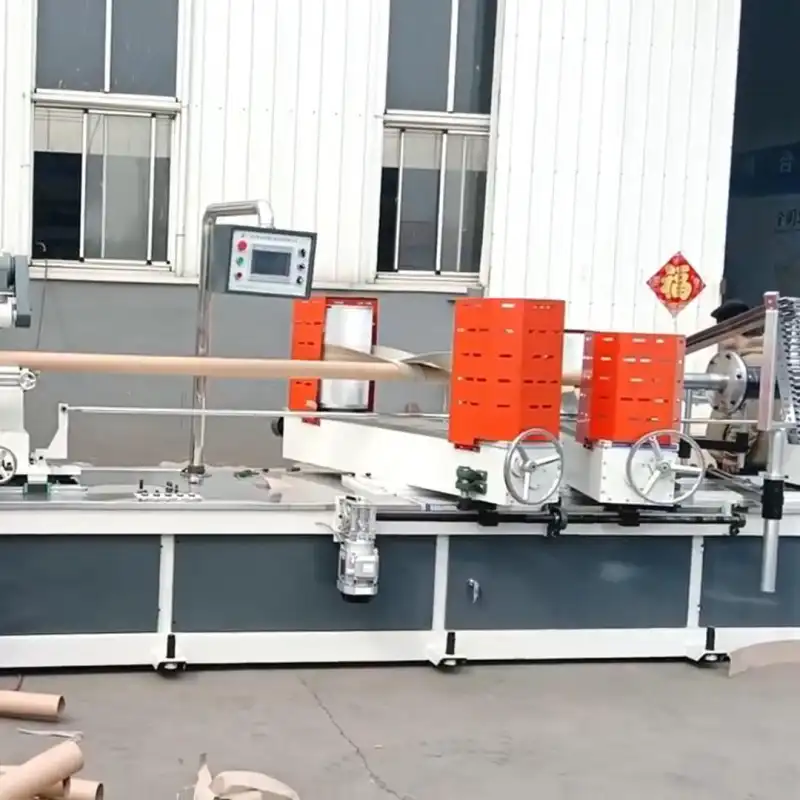

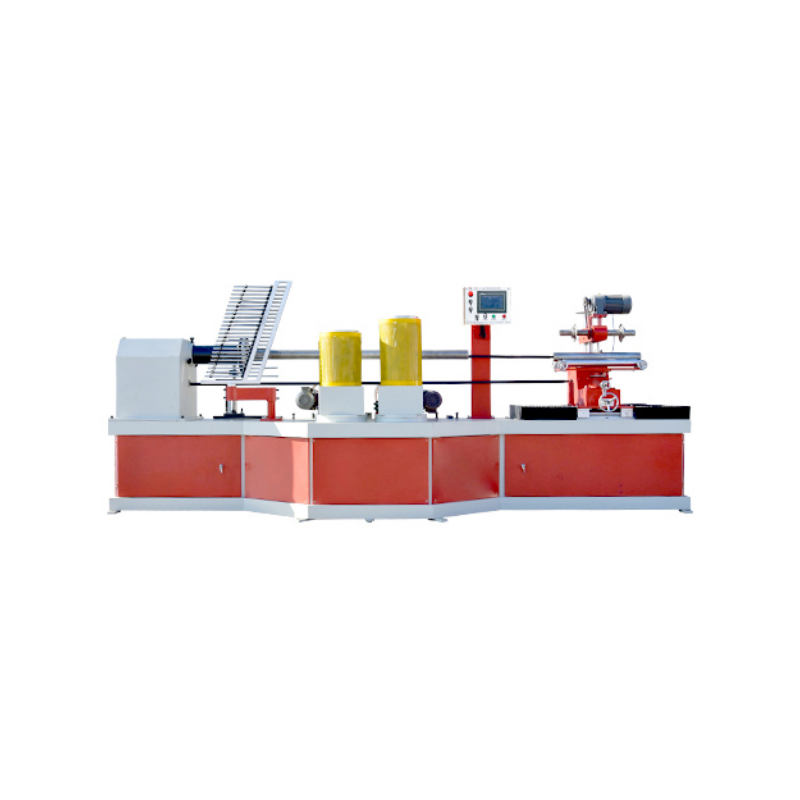

The paper core making machine price is different based on many factors.In the rapidly evolving packaging and paper processing industry, the demand for precision, efficiency, and reliability in paper core production has never been higher. Qingdao New Richuan Precision Machine Co., Ltd. (NRC MACHINE) stands at the forefront of innovation with its advanced Paper Core Making Machine, engineered to meet the diverse needs of modern manufacturing. Designed for stability, versatility, and high automation, this machine delivers consistent quality and exceptional performance across a wide range of applications.

This document provides a comprehensive overview of the machine’s specifications, features, and pricing insights, highlighting why NRC MACHINE is a trusted partner for industrial paper core solutions.

-

Machine Overview and Key Specifications

The paper core making machine manufactured by NRC MACHINE is a state-of-the-art system tailored for producing high-quality paper cores used in textiles, printing, paper converting, and other roll-processing industries. Below are the core technical parameters:

- Inner Diameter Range:30–200 mm

(Adjustable to accommodate various core sizes for different industrial applications) - Wall Thickness:1–15 mm

(Supports customization from thin-walled to heavy-duty cores) - Production Speed:0–40 meters per minute

(Variable speed control for optimal efficiency and material handling) - Drive System:Servo Motor Driver

(Ensures precise control, smooth operation, and energy efficiency) - Control System:CNC Controller (Delta Brand)

(Offers user-friendly interface, high stability, and intelligent automation)

These specifications make the machine ideal for medium to high-volume production environments requiring flexibility and precision.

-

Advanced Features and Technological Advantages

3.1 Precision Engineering and Durability

Constructed with high-grade components and reinforced structural design, the machine ensures long-term stability and minimal maintenance. The use of premium materials in critical parts enhances wear resistance and extends service life.

3.2 Intelligent CNC Control (Delta Brand)

The integration of a Delta-brand CNC controller enables real-time monitoring, fault diagnostics, and parameter adjustments. Operators can save multiple production recipes, reducing setup time and minimizing human error.

3.3 Servo Motor Drive System

The servo motor system provides accurate tension control and synchronized operation across all stages of core winding. This results in uniform paper core density, smooth surface finish, and consistent dimensional accuracy.

3.4 Wide Range of Customization

With an inner diameter range from 30 mm to 200 mm and wall thickness adjustable between 1 mm and 15 mm, the machine supports production of cores for labels, films, foils, and industrial rolls—making it highly adaptable to diverse customer needs.

3.5 User-Friendly Operation and Safety

The machine is equipped with an intuitive HMI (Human-Machine Interface), emergency stop functions, and safety guarding, ensuring a safe and efficient working environment. Training is minimal due to the logical layout and clear operational guidance.

-

Performance and Application Scope

The NRC paper core making machine excels in producing cores for:

- Label and adhesive tape manufacturing

- Flexible packaging and laminating lines

- Printing and paper converting

- Textile and nonwoven roll storage

- Industrial film and foil winding

Its variable speed (0–40 m/min) allows for gentle handling of delicate materials while maintaining high output when needed. The consistent core quality reduces waste and improves downstream processing efficiency.

-

Pricing Information and Value Proposition

5.1 Transparent and Competitive Pricing

The price of the NRC paper core making machine varies based on configuration, optional accessories, and order quantity. While exact figures are provided upon request to ensure accuracy, the machine is positioned as a mid-to-high-end solution offering exceptional value for money.

Typical pricing factors include:

- Base model vs. fully automated version

- Choice of raw material feeding system (manual, semi-automatic, or automatic)

- Additional rollers, drying units, or cutting modules

- Voltage and power specifications for different regions

5.2 Long-Term ROI and Cost Efficiency

Despite the initial investment, the machine delivers significant long-term savings through:

- Reduced labor costs due to automation

- Lower material waste from precise control

- Minimal downtime and maintenance requirements

- Energy-efficient servo drive technology

Customers report a return on investment within 12–18 months under regular operation.

5.3 After-Sales Support and Global Service Network

NRC MACHINE offers comprehensive support including:

- On-site installation and commissioning

- Operator training (onsite or remote)

- Spare parts supply and technical troubleshooting

- Software updates and remote diagnostics

This support structure enhances the overall value and ensures continuous operation for clients worldwide.

-

Why Choose NRC MACHINE?

Qingdao New Richuan Precision Machine Co., Ltd. has built a strong reputation for delivering reliable, innovative, and customer-focused machinery. With years of R&D experience and a commitment to quality, NRC MACHINE combines German-level precision with competitive Chinese manufacturing advantages.

Key reasons to choose NRC:

- Proven performance in global markets

- Use of world-renowned components (e.g., Delta CNC, servo systems)

- Customization capability to meet specific production needs

- Fast delivery and responsive customer service

- CE-certified designs ensuring compliance with international safety standards

-

Conclusion

The paper core making machine from NRC MACHINE represents a powerful blend of precision, versatility, and intelligent control. With its wide processing range (inner diameter: 30–200 mm, wall thickness: 1–15 mm), variable speed (0–40 m/min), servo motor drive, and Delta CNC controller, it is engineered to deliver consistent, high-quality output for a variety of industrial applications.

While the exact price depends on customization and order details, the machine’s performance, durability, and after-sales support make it a cost-effective and future-ready investment. For businesses aiming to enhance production efficiency and product quality, NRC MACHINE offers a trusted solution backed by technical excellence and global service capability.

Contact NRC MACHINE today for a detailed quotation and technical consultation.