Revolutionizing Paper Tube Production: The Future with CNC Controlled Paper Tube Making Equipment

-

Introduction: Redefining Efficiency in Paper Tube Manufacturing

In the ever-evolving world of packaging and industrial materials, paper tubes have emerged as a sustainable, cost-effective, and versatile solution across industries—from textiles and paper processing to construction and consumer goods. As demand grows, so does the need for precision, speed, and customization in production. Enter the CNC controlled Paper Tube Making Equipment, a game-changing innovation that is transforming the way paper tubes are manufactured. Engineered for excellence and built with cutting-edge technology, this equipment sets a new benchmark in automation, accuracy, and scalability.

-

The Power of CNC: Precision at Its Core

At the heart of modern paper tube manufacturing lies the CNC controlled Paper Tube Making Equipment, a system that leverages computer numerical control (CNC) to automate every stage of the tube-forming process. Unlike traditional mechanical machines that rely on manual adjustments and fixed settings, CNC technology enables real-time control over diameter, thickness, speed, and winding patterns. This ensures consistent quality, minimal material waste, and unmatched repeatability.

The integration of a CNC controller and servo motor driver allows for seamless transitions between different tube specifications. Whether you’re producing lightweight cores for adhesive tapes or heavy-duty tubes for industrial textiles, the system adapts instantly—ensuring optimal performance across diverse applications.

-

Key Specifications: Built for Versatility and Performance

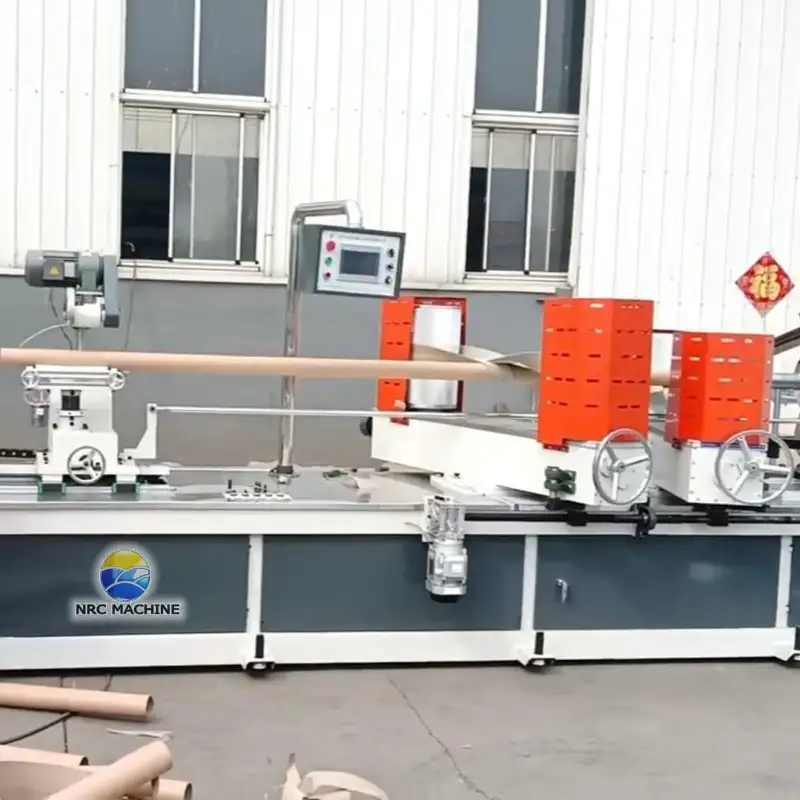

The CNC controlled Paper Tube Making Equipment, made by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd), is designed to meet the demands of global manufacturers seeking flexibility and reliability. Here are its standout technical features:

- Inner Diameter Range: 30~200mm – accommodating a wide variety of core sizes

- Wall Thickness: 1~15mm – suitable for light to heavy-duty applications

- Production Speed: 0~40m/min – fully adjustable to match production needs

- Drive System: High-precision servo motor driver for smooth, responsive control

- Control System: Advanced CNC controller for intelligent operation and data monitoring

- Customization Support: Fully customizable to meet specific client requirements, including material feeding systems, cutting mechanisms, and output configurations

These specifications make the machine ideal for industries requiring high-volume, high-consistency output without compromising on quality.

-

Why Choose CNC Over Conventional Machines?

Traditional paper tube machines often struggle with changeover times, precision inconsistencies, and limited adaptability. In contrast, the CNC controlled Paper Tube Making Equipment offers several distinct advantages:

- Automated Parameter Adjustment: No more manual recalibration. Simply input the desired specs, and the CNC system adjusts roll gaps, tension, and speed automatically.

- Real-Time Monitoring & Diagnostics: The CNC controller provides real-time feedback on machine status, enabling predictive maintenance and reducing downtime.

- Scalability: Whether you’re a small-scale producer or a large factory, the machine scales with your business. Add modules, integrate with existing lines, or expand production capacity with ease.

- Energy Efficiency: Servo-driven systems consume power only when in motion, significantly reducing energy consumption compared to constant-speed drives.

-

Customization: Tailored to Your Unique Needs

One of the most compelling features of this equipment is its support for customization. Made by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd), the machine is not a one-size-fits-all solution. Instead, it is engineered to adapt to your unique production environment and product requirements.

Need a special glue application system for eco-friendly adhesives? Want to integrate an automatic stacking unit? Or perhaps you require a non-standard diameter range beyond the standard 30~200mm? The team at NRC MACHINE works closely with clients to deliver tailored solutions that enhance productivity and reduce operational friction.

This level of customization ensures that the CNC controlled Paper Tube Making Equipment isn’t just a machine—it’s a strategic partner in your manufacturing ecosystem.

-

Sustainability and the Future of Packaging

As the world shifts toward sustainable packaging solutions, paper tubes are gaining prominence as a renewable, recyclable alternative to plastic and metal cores. The CNC controlled Paper Tube Making Equipment plays a crucial role in this transition by enabling efficient, low-waste production of high-strength paper tubes.

With precise control over material usage and glue application, the machine minimizes excess and ensures that every tube meets environmental standards without sacrificing durability. This makes it an ideal choice for eco-conscious brands looking to reduce their carbon footprint while maintaining product integrity.

-

Global Reach, Local Support: Backed by NRC MACHINE

NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd) is a trusted name in precision engineering, with years of experience in developing advanced machinery for the paper and packaging industries. Their commitment to innovation, quality, and customer satisfaction is reflected in every unit of the CNC controlled Paper Tube Making Equipment they produce.

With a global service network, comprehensive training programs, and responsive technical support, NRC MACHINE ensures that your investment is protected and your operations run smoothly—no matter where you are in the world.

-

Conclusion: Embrace the Future of Tube Making Today

The future of paper tube manufacturing is here—and it’s powered by CNC technology. The CNC controlled Paper Tube Making Equipment, made by NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd), combines precision, versatility, and intelligence to deliver unmatched performance. With its wide range of specifications (inner diameter: 30~200mm, thickness: 1~15mm, speed: 0~40m/min), servo motor driver, CNC controller, and full customization support, it stands as a cornerstone of modern, efficient, and sustainable production.

Whether you’re upgrading your current line or building a new facility, choosing CNC-controlled automation is not just an upgrade—it’s a transformation. Step into the future of manufacturing with confidence, knowing you have the most advanced technology on your side.