Parallel Paper Tube Making Machine: Precision & Efficiency Redefined

Today’s Date: November 26, 2025 | Wednesday

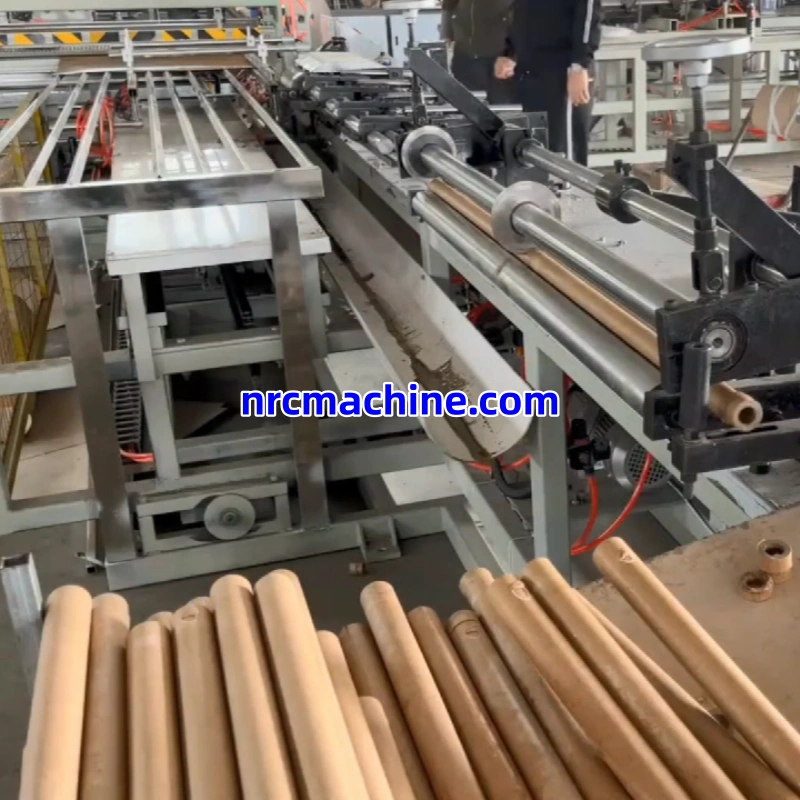

Looking for a high-performance solution to streamline your paper tube production? Meet the Parallel Paper Tube Making Machine—a game-changer designed to deliver unmatched precision, speed, and versatility for modern manufacturing needs. Whether you’re producing tubes for textiles, packaging, or industrial applications, this automatic powerhouse ticks all the right boxes. Let’s dive into what makes it stand out.

✨ Key Specifications: Built for Flexibility

The magic starts with its wide range of adaptable parameters, ensuring it fits seamlessly into diverse production scenarios:

- Inner Diameter Range: 16–76mm

(Perfect for small textile bobbins to larger industrial cores—no need for multiple machines!) - Wall Thickness: 1–5mm

(Handles thin, lightweight tubes to thick, durable ones with consistent quality.) - Maximum Length: Up to 1500mm

(Ideal for long tubes used in construction, printing, or heavy-duty packaging.)

This flexibility means you can switch between product types effortlessly—no more downtime for manual adjustments or equipment changes.

⚙️ Automatic Operation: Less Effort, More Output

Say goodbye to labor-intensive processes! This machine is fully automatic, covering the entire workflow:

- Paper Feeding: Auto-loads raw paper rolls, reducing manual handling.

- Gluing & Rolling: Precisely applies adhesive and rolls paper into tubes with zero gaps or wrinkles.

- Cutting & Ejection: Cuts tubes to your specified length and ejects finished products smoothly.

- Stacking (Optional): Some models even include auto-stacking for further efficiency.

Result? One operator can manage the entire process, slashing labor costs while boosting output by up to 300% compared to manual methods.

🌟 Why It Stands Out: 3 Core Advantages

- Consistent Quality, Every Time

Advanced sensors and precision rollers ensure uniform inner diameter, wall thickness, and length—no more rejected products due to size deviations. - Time-Saving & Cost-Effective

Produces up to 60+ tubes per minute (depending on size), cutting production time in half. Plus, its energy-efficient design lowers electricity costs. - User-Friendly & Low Maintenance

Equipped with an intuitive touchscreen interface—adjust settings in seconds. Built with durable materials (like stainless steel) to resist wear and tear, minimizing maintenance downtime.

📦 Ideal Applications: Where It Shines

This machine isn’t picky! It’s perfect for:

- Textile Industry: Bobbins, spools, and warp beams.

- Packaging Sector: Core tubes for paper rolls, plastic films, and adhesive tapes.

- Industrial Use: Tubes for construction materials, printing, and electrical insulation.

- Custom Projects: Handles special sizes (within the 16–76mm diameter range) with ease.

🔧 Installation & Support: Hassle-Free Setup

Worried about getting started? Don’t be! Most suppliers offer:

- On-Site Installation: Engineers set up and calibrate the machine at your facility.

- Training: Hands-on sessions for your team to master operation and maintenance.

- After-Sales Service: 24/7 technical support and spare parts supply.

📝 Final Thoughts: A Smart Investment

For manufacturers tired of slow, inconsistent manual tube production, this Parallel Paper Tube Making Machine is a no-brainer. It combines flexibility (thanks to its wide size range), efficiency (with full automation), and reliability (through robust design) to transform your workflow.

Ready to upgrade? Reach out to trusted suppliers for a demo or quote—your future self (and your bottom line) will thank you!

Hashtags:

#PaperTubeMachine #ManufacturingTech #Automation #IndustrialInnovation #PackagingSolutions #TextileMachinery #CostSaving #FactoryUpgrade #PaperTubeProduction #SmartManufacturing #2025Tech

**Follow for more insights on industrial equipment and production tips!