Spiral Cardboard Core Pipe Paper Tube Rolling Machine: An In-Depth Overview

1. Introduction to Spiral Cardboard Core Pipe Paper Tube Rolling Machine

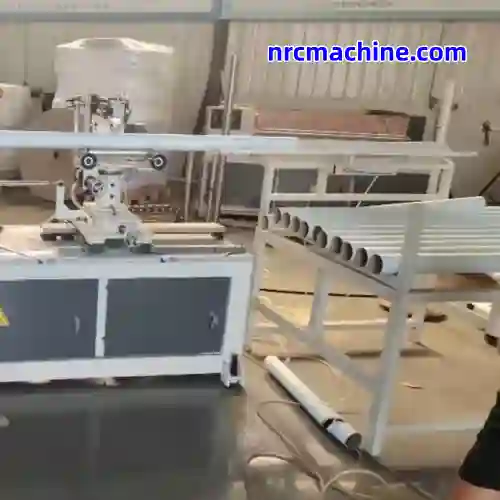

The spiral cardboard core pipe paper tube rolling machine is a specialized industrial equipment designed for manufacturing high-quality spiral-wound cardboard cores and paper tubes. Widely used in packaging, textile, printing, and construction industries, this machine transforms raw paper materials (such as kraft paper, corrugated paper) into cylindrical tubes with precise dimensions and strong structural integrity. Its core advantage lies in the spiral winding technology, which ensures uniform thickness, high compressive strength, and excellent durability of the finished products, meeting the diverse needs of industrial production.

2. Core Components and Structure

The machine consists of several key components that work synergistically to achieve efficient production. The unwinding unit holds multiple paper rolls, enabling continuous feeding without frequent interruptions. The gluing system applies eco-friendly adhesive evenly on the paper surface, ensuring firm bonding during winding. The spiral winding mechanism is the core part, which twists the paper strips at a specific angle and rolls them into tubes with adjustable diameters (ranging from 10mm to 300mm typically). The cutting unit uses precision blades to trim the continuous tube into desired lengths, while the control panel allows operators to set parameters such as speed, diameter, and cutting length, realizing automated operation.

3. Working Principle and Process

The production process of the spiral cardboard core machine is streamlined and efficient. First, raw paper rolls are loaded onto the unwinding unit, and the paper strips are guided through tension control devices to maintain stability. Next, the gluing system coats one side of the paper with adhesive, and the strips are fed into the spiral winding mechanism. Here, the paper is twisted spirally around a mandrel, with each layer overlapping to form a dense, strong tube. As the tube advances, the cutting unit trims it to the preset length automatically. Finally, the finished cardboard cores are collected, inspected, and packaged for delivery. The entire process is automated, with a production speed of 20-50 meters per minute, significantly improving production efficiency.

4. Technical Advantages

This machine boasts several prominent technical advantages. Firstly, the spiral winding design ensures high radial and axial compressive strength of the paper tubes, making them suitable for heavy-load applications. Secondly, the adjustable diameter and length settings allow flexible customization to meet different industry requirements. Thirdly, the automated control system reduces manual intervention, minimizing errors and improving production consistency. Additionally, the use of eco-friendly adhesives and recyclable paper materials aligns with environmental protection trends, enhancing the machine’s market competitiveness.

5. Technical Parameters

| Parameter Category | Specifications |

| Tube Dimensions | – Inner diameter: 30mm – 150mm (customizable up to 500mm for special models)- Wall thickness: 1mm – 10mm (adjustable via paper layer quantity)- Length range: 200mm – 6000mm (continuous cutting with ±1mm precision) |

| Production Capacity | – Speed: 20m – 40m/min (varies by tube diameter and thickness)- Maximum paper layer: 1-16 layers- Daily output: 8,000m – 20,000m (based on 8-hour working shift) |

| Raw Material Requirements | – Paper width: 50mm – 105mm- Paper grammage: 80g/m² – 400g/m² (kraft paper, corrugated paper, specialty paper)- Adhesive type: Water-based, eco-friendly hot-melt adhesive |

| Power and Energy | – Main motor power: 3.0kW – 7.5kW (3-phase, 380V/50Hz)- Gluing system power: 0.55kW – 1.5kW- Total power consumption: 4.0kW – 9.0kW/h |

| Machine Dimensions | – Length: 3500mm – 5500mm- Width: 1200mm – 1800mm- Height: 1500mm – 2200mm- Net weight: 800kg – 2500kg (depending on model) |

| Control System | PLC control with touch screen interface |

6. Application Fields

The spiral cardboard core pipe paper tube rolling machine has a wide range of applications. In the packaging industry, it produces paper tubes for wrapping films, tapes, and textiles. In the printing industry, it manufactures cores for printing rolls and paper rolls. In the construction industry, it supplies cardboard tubes for concrete pouring and reinforcement. Moreover, it is used in the textile industry for yarn winding and the electronic industry for cable packaging. Its versatility and reliability make it an indispensable equipment in various industrial sectors.

7. Maintenance and Operation Tips

To ensure the machine’s long-term stable operation, proper maintenance is essential. Regularly check and clean the gluing system to prevent adhesive clogging. Inspect the cutting blades for sharpness and replace them when necessary. Lubricate the moving parts regularly to reduce friction and wear. Additionally, operators should receive professional training to master the control panel operations and safety precautions. Avoid overloading the machine and follow the recommended production parameters to prevent mechanical failures. With proper maintenance and operation, the machine can maintain high production efficiency and extend its service life.