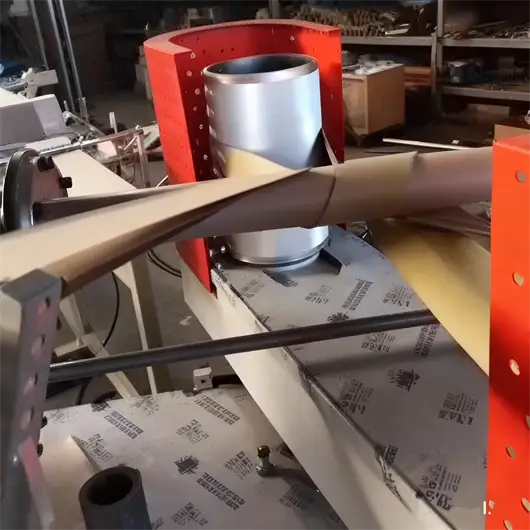

NRC150C Spiral Paper Tube Making Machine

1.Introduction

The NRC150C Model Spiral Paper Tube Making Machine represents a pinnacle of innovation in the paper tube manufacturing industry. Engineered for efficiency, precision, and reliability, this advanced machinery is designed to meet the growing global demand for high-quality spiral-wound paper tubes. These tubes are widely used in sectors such as textiles, packaging, construction, and industrial materials, where strength, consistency, and customization are paramount. The NRC150C stands out as a versatile and high-performance solution for modern manufacturing environments.

2.Key Features and Technical Specifications

The NRC150C integrates cutting-edge technology with robust mechanical design to deliver superior output. Its key features include:

- Automatic Gluing and Winding System: Ensures consistent adhesive application and precise spiral winding, resulting in uniform tube thickness and enhanced structural integrity.

- Adjustable Tube Diameter Range: Supports tube production from 20mm to 150mm, making it ideal for diverse applications—from small cores to large industrial tubes.

- High-Speed Operation: Capable of producing up to 60 meters per minute, significantly boosting productivity and reducing production cycles.

- PLC Control System: Equipped with an intuitive touch-screen interface, enabling operators to monitor and adjust settings with ease, including speed, tension, and cutting length.

- Precision Cutting Mechanism: Features an automated cutting unit that ensures clean, accurate cross-sections with minimal waste.

- Durable Construction: Built with high-grade stainless steel and wear-resistant components to ensure longevity and minimal maintenance.

3.Operational Efficiency and Automation

One of the NRC150C’s most significant advantages is its high level of automation. The machine seamlessly integrates unwinding, gluing, forming, drying, and cutting processes into a single continuous workflow. This reduces labor requirements and minimizes human error. Additionally, the machine supports quick changeovers between different tube specifications, enhancing production flexibility. Energy-efficient motors and optimized drying systems further reduce power consumption, aligning with sustainable manufacturing practices.

4.Applications and Market Relevance

Spiral paper tubes produced by the NRC150C are used across multiple industries:

- Textile Industry: For yarn and thread winding.

- Packaging Sector: As cores for labels, films, and tapes.

- Construction: For concrete forms and protective casings.

- Renewable Energy: In the production of wind turbine components.

Its ability to produce strong, lightweight, and eco-friendly tubes makes it a preferred choice in markets prioritizing sustainability.

5.Conclusion and Strategic Value

The NRC150C Model Spiral Paper Tube Making Machine is not merely a piece of equipment—it is a strategic investment in operational excellence. By combining automation, precision, and versatility, it empowers manufacturers to scale production, reduce costs, and meet stringent quality standards. As global demand for sustainable packaging and industrial materials continues to rise, the NRC150C positions businesses at the forefront of innovation, efficiency, and environmental responsibility. For forward-thinking enterprises, this machine is a cornerstone of modern manufacturing success.

6.Technical Parameter

| Tube diameter | 20-150mm |

| Number of paper layer | 16 layers |

| Tube max thickness | 8mm |

| Rewinding noses | 2 |

| Operator | 1-2 |

| Productive speed | 3-30m/min |

| Way of cutting | Servo motor cutter |

| Way of gluing | Double sides |

| Paper shaft type | Crisscross |

| Way of tube down | Withdraw |

| Power of mainframe | 11kw |

| Power input | 380V |