NRC MACHINE: A Professional Factory for Spiral Tube Making Machines

1.Introduction

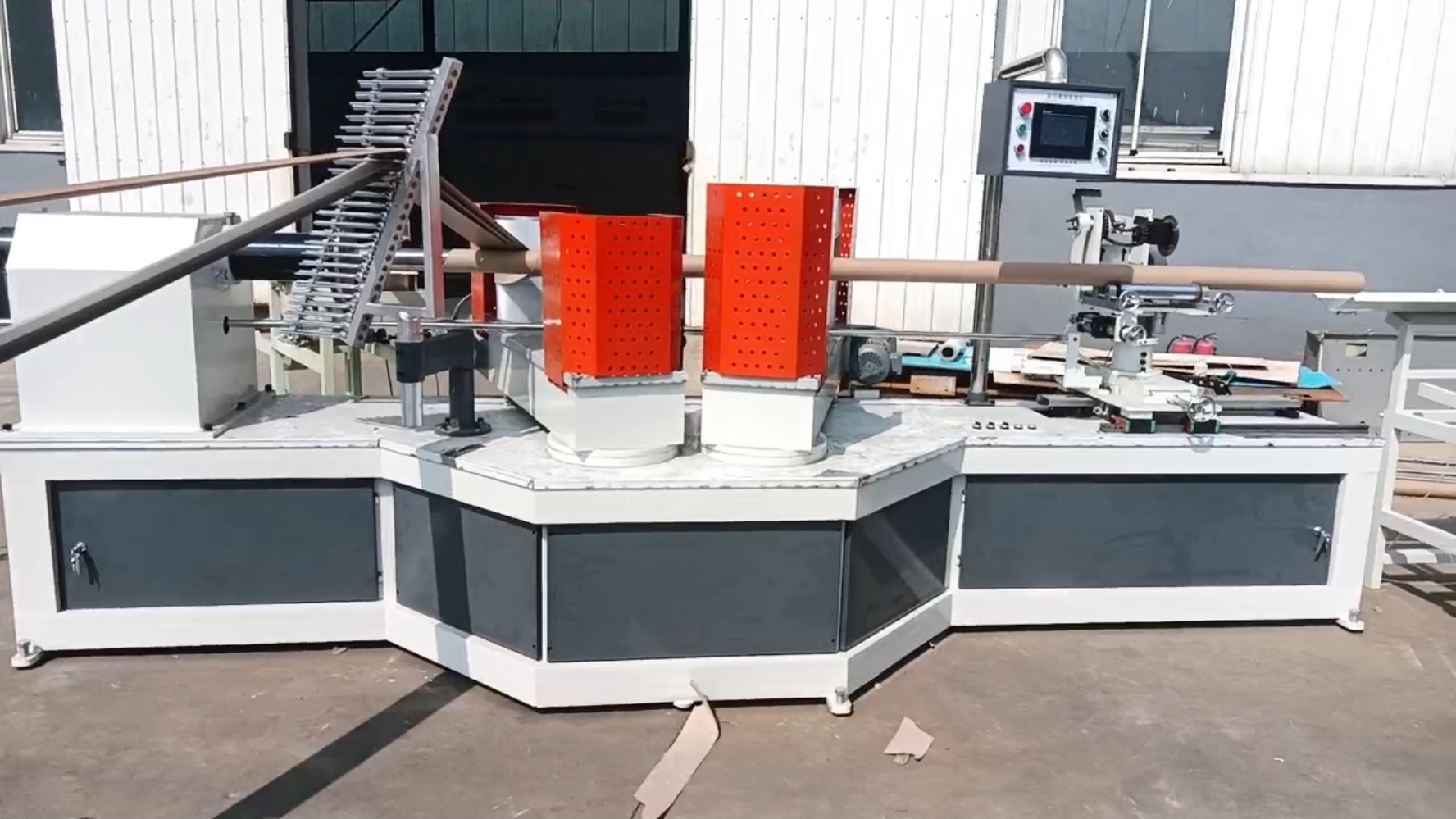

NRC MACHINE stands as a leading manufacturer and professional factory specializing in the production of Spiral Tube Making Machine. With years of expertise in the industry, NRC MACHINE has built a strong reputation for delivering high-quality, reliable, and innovative machinery solutions tailored to meet the diverse needs of global clients. As a dedicated Spiral Tube Making Machine Manufacturer, NRC MACHINE is committed to excellence in engineering, precision manufacturing, and customer satisfaction.

2.Core Expertise and Product Range

NRC MACHINE focuses exclusively on the design, development, and production of spiral tube forming equipment. Their product line includes fully automatic, semi-automatic, and customized spiral tube making machines capable of producing tubes from various materials such as steel, aluminum, and other metal coils. These machines are widely used in industries including HVAC, construction, automotive, and industrial piping. Each machine is engineered for high efficiency, consistent output, and long-term durability, ensuring optimal performance in demanding production environments.

3.Advanced Technology and Innovation

At the heart of NRC MACHINE’s success is its commitment to innovation. The company integrates advanced automation, CNC control systems, and intelligent monitoring technologies into its machines. This ensures precise tube dimensions, smooth operation, and minimal material waste. Continuous research and development enable NRC MACHINE to stay ahead of industry trends and offer cutting-edge solutions that enhance productivity and reduce operational costs for clients.

4.Quality Assurance and Certification

NRC MACHINE adheres to international quality standards throughout the manufacturing process. All machines undergo rigorous testing and quality checks to ensure compliance with global safety and performance regulations. The company holds relevant certifications, reflecting its dedication to quality, reliability, and customer trust.

5.Global Reach and Customer Support

Serving clients across Asia, Europe, the Middle East, and the Americas, NRC MACHINE has established a robust global distribution network. The company offers comprehensive after-sales services, including installation, training, technical support, and spare parts supply, ensuring seamless integration and operation of its machines.

6.Conclusion

As a trusted Spiral Tube Making Machine Manufacturer, NRC MACHINE continues to drive innovation, quality, and customer satisfaction. With a professional factory, advanced technology, and a global outlook, NRC MACHINE is a partner of choice for businesses seeking efficient and reliable tube manufacturing solutions.

7.Technical Parameter

| Technical Parameters | Control System | ||

| Number of winding paper layers | 3-21 layers | PLC Controller | Delta Brand |

| Maximum coil diameter | 200mm | HMI | Color touch screen |

| Minimum coil diameter | 30mm | Program Version | HT/4.0 |

| Maximum coil thickness | 12 mm | Frequency Converter | Shenzhen EasyDrive |

| Minimum coil thickness | 1mm | Actuators (contactors, etc.) | China Chint Products |

| Core mold fixing method | Flange tightening | Signal components (photoelectric switches, etc.) | Omron Products |

| Winding head | Two head single belt | Pneumatic Components | Hengyi Products |

| Cutting method | Single blade cutting | Angle adjustment motor | Cazenove |

| Gluing method | Single/double-sided gluing | Synchronous control | X-axis servo screw |

| Fixed length method | Encoder pulse fixed length | Synchronous tracking pipe cutting system | Servo synchronous tracking multi-knife cutting |

| Number of operators | 1-2 people | ||

| Hose reel speed | 3-30 m/min | Equipped with equipment | |

| Input Power | 380V three-phase four-wire customization | Automatic pipe rack | have |

| Standard sizes | Belt diagonal | electric | |

| Host size: length × width × height | 4500mm × 1800mm × 1750mm | Belt tension adjustment | Automatic adjustment |

| Floor space: length × width | 18m × 8m | Mainframe swing angle | automatic |

| Hub height | 400mm | Automatic glue supply | Air-operated diaphragm pumps |

| Minimum wheelbase | 750mm | Automatic lubrication of paper tape | automatic |

| Maximum wheelbase | 950mm | Tension adjustment | Mechanical adjustment |

| Total mass | 3200kg | Paper holder type | Overall paper holder |

| monitor rate | 15 KW | Included accessories | |

| Wheel speed | 47r/min | Tube winding mandrel | 1 set. |