Spiral Winding Machines for Making Paper Tube: Advanced Solutions from NRC MACHINE

In the modern packaging and industrial manufacturing sectors, the demand for high-quality, durable paper tubes has surged. These tubes are widely used in textiles, printing, paper processing, and construction industries. To meet this growing need, spiral winding machines for making paper tube have become essential equipment in production lines. Among the leading manufacturers, NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd) stands out with its advanced technology and reliable performance.

What Are Spiral Winding Machines for Making Paper Tube?

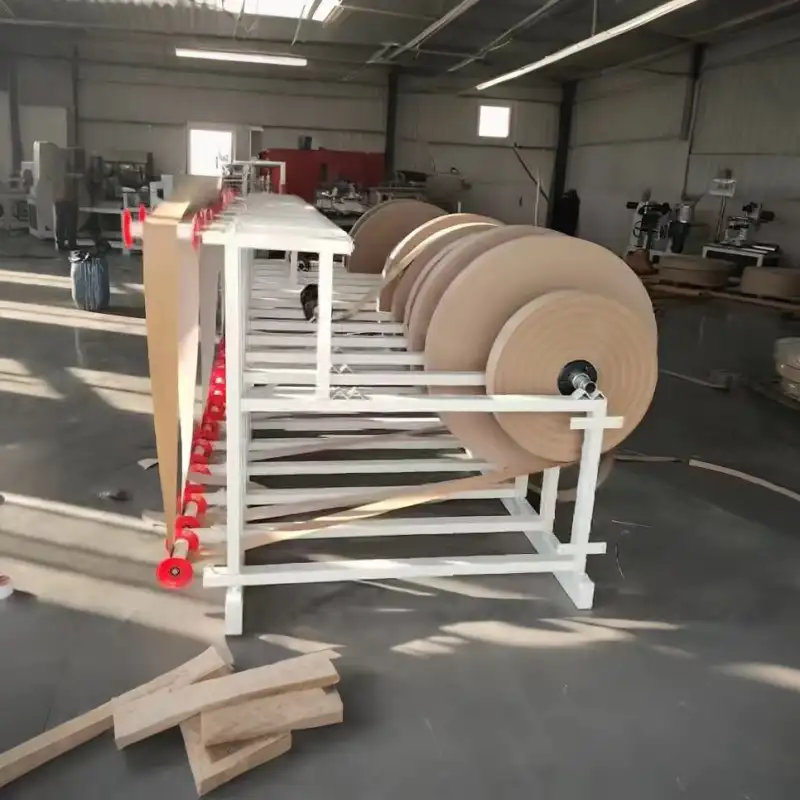

Spiral winding machines for making paper tube are specialized industrial machines designed to produce continuous paper tubes through a helical (spiral) layering process. Unlike traditional flat-winding methods, spiral winding allows for stronger, more uniform tubes with consistent thickness and enhanced structural integrity. The process involves feeding multiple layers of paper or kraft material onto a rotating mandrel at a specific angle, bonding them with adhesive, and compressing them into a solid cylindrical form.

These machines are ideal for producing large-diameter tubes used in applications such as textile bobbins, paper rolls, and industrial cores. With the capability to handle inner diameters ranging from 70 to 420 mm and wall thicknesses between 5 to 20 mm, NRC MACHINE’s models offer exceptional flexibility for diverse production requirements.

Key Features of NRC MACHINE’s Spiral Winding Solutions

NRC MACHINE, a trusted name in precision engineering, offers state-of-the-art spiral winding machines for making paper tube that combine efficiency, accuracy, and durability. Here are some of the standout features:

- Precision Control System: Equipped with PLC (Programmable Logic Controller) and touch-screen HMI (Human-Machine Interface), the machine ensures accurate control over winding speed, tension, and diameter.

- Multi-Layer Capability: Supports up to 30 layers of paper rolls, allowing for thick-walled, high-strength tubes suitable for heavy-duty applications.

- Adjustable Inner Diameter (70–420 mm): The machine can be quickly reconfigured for different tube sizes, minimizing downtime during product changeovers.

- High-Efficiency Gluing System: Ensures even adhesive application for strong bonding between layers, preventing delamination.

- Robust Construction: Built with heavy-duty components and corrosion-resistant materials, ensuring long service life even in high-utilization environments.

- Automated Operation: Reduces labor costs and human error, increasing overall productivity.

These features make NRC MACHINE’s spiral winders ideal for medium to large-scale manufacturers seeking consistency and scalability.

Applications and Industry Benefits

The versatility of spiral winding machines for making paper tube enables their use across various industries:

- Textile Industry: For producing strong, heat-resistant bobbins used in yarn winding and weaving.

- Paper & Printing: Manufacturing cores for large paper rolls used in printing presses and converting lines.

- Construction & Packaging: Creating robust tubes for concrete forms, protective packaging, and transport cores.

- Recycling & Material Handling: Producing eco-friendly, reusable cores and spools.

By using NRC MACHINE’s equipment, companies benefit from reduced material waste, higher production speeds, and improved product consistency—key factors in maintaining a competitive edge.

Why Choose NRC MACHINE (Qingdao New Richuan Precision Machine Co., Ltd)?

As a professional manufacturer based in Qingdao, China, NRC MACHINE is committed to innovation and customer satisfaction. Their spiral winding machines are engineered to meet international standards, with CE certification and global technical support.

- Customization Options: Machines can be tailored to specific production needs, including special diameters, layer counts, and automation levels.

- After-Sales Support: Comprehensive installation guidance, training, and maintenance services ensure smooth operation.

- Global Reach: Exported to multiple countries, with a growing presence in Asia, Europe, and North America.

With a strong R&D team and a focus on sustainable manufacturing, NRC MACHINE continues to lead the way in paper tube machinery innovation.

Conclusion: The Future of Paper Tube Production

As industries demand more sustainable and cost-effective packaging solutions, the role of spiral winding machines for making paper tube will only grow. NRC MACHINE’s advanced technology, combined with reliable performance and customer-centric service, positions it as a top choice for manufacturers worldwide. Whether you’re producing textile bobbins or industrial cores, investing in a high-quality spiral winder from NRC MACHINE ensures long-term success.

Upgrade your production line today with NRC MACHINE’s cutting-edge spiral winding machines for making paper tube—where precision meets performance.